Our Service

What products and services do we offer

Fluid Tech Group provides malleable cast iron galvanized pipe fittings, black iron pipe fittings, ductile iron grooved pipe fittings, fire valves and fittings, water valves and fittings, seismic brackets, carbon steel fast pressing pipe fittings, gas pipe fittings and other piping products in fluid delivery systems for fire and water systems. At the same time, because it has five production bases, it can provide one-stop procurement, coordinate production, inspection, loading and delivery. In addition, free professional technical and product consultation; Free market research reports; Free marketing promotion services; Free samples, 7*24 service, etc.

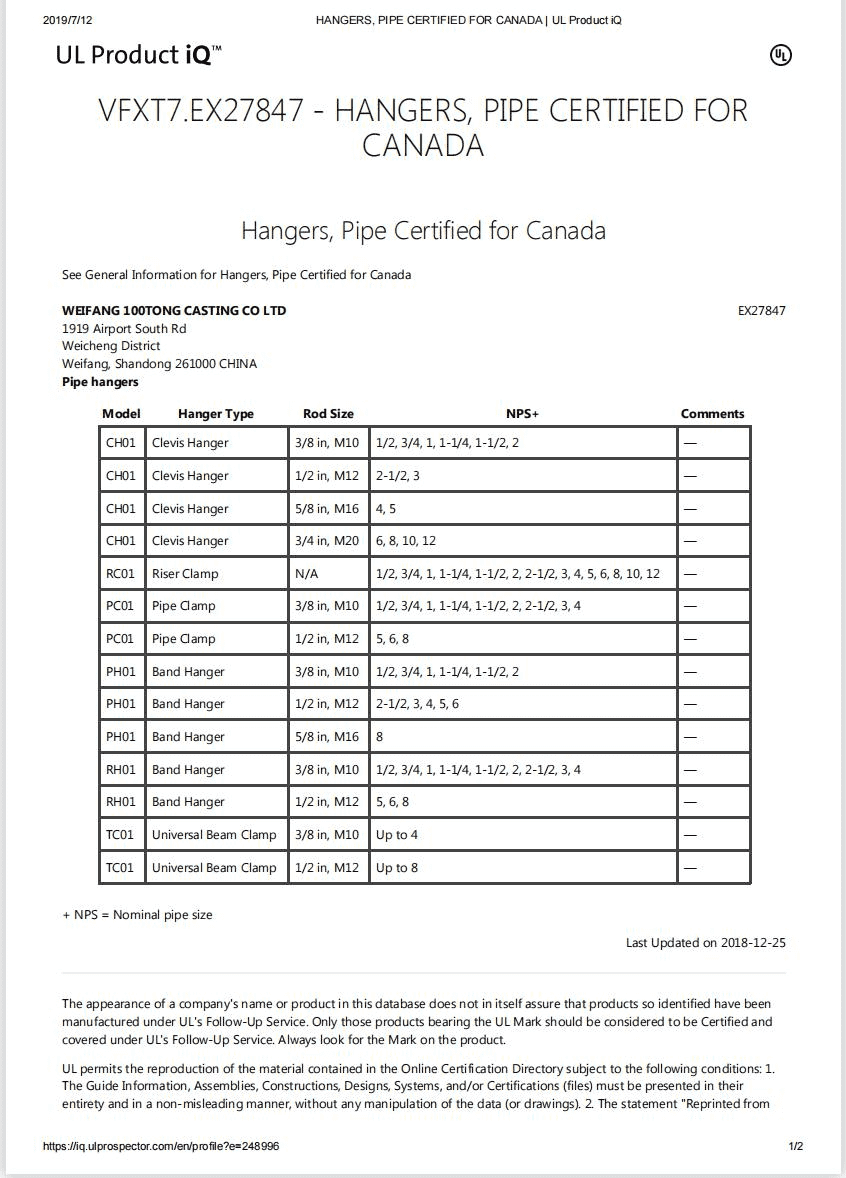

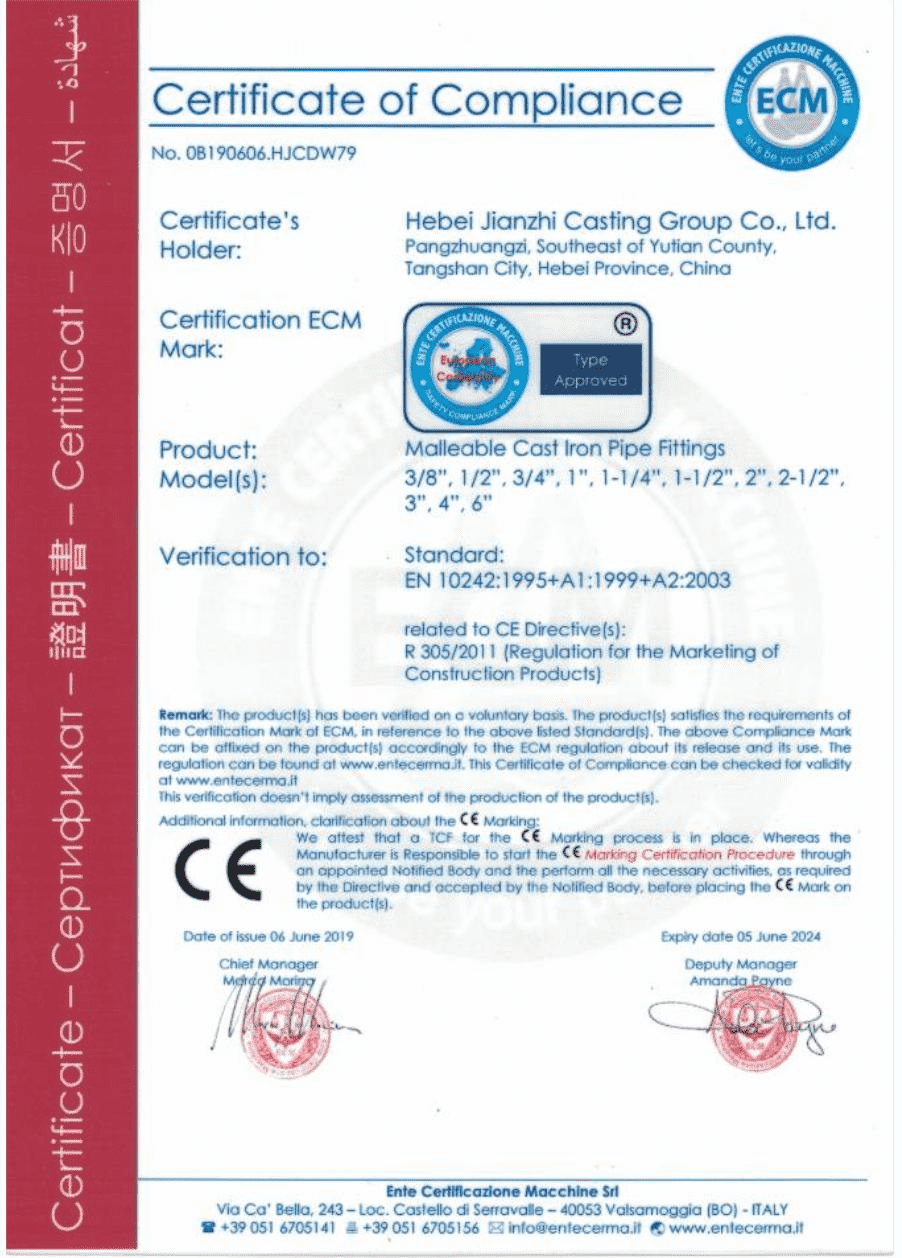

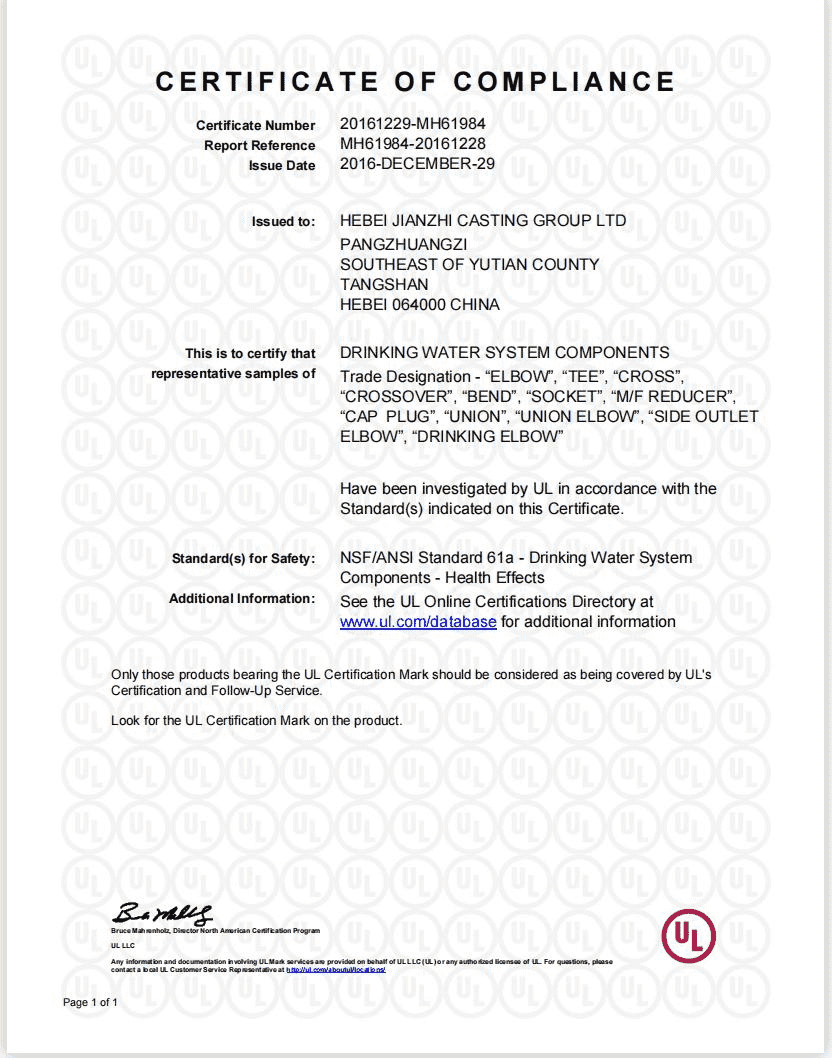

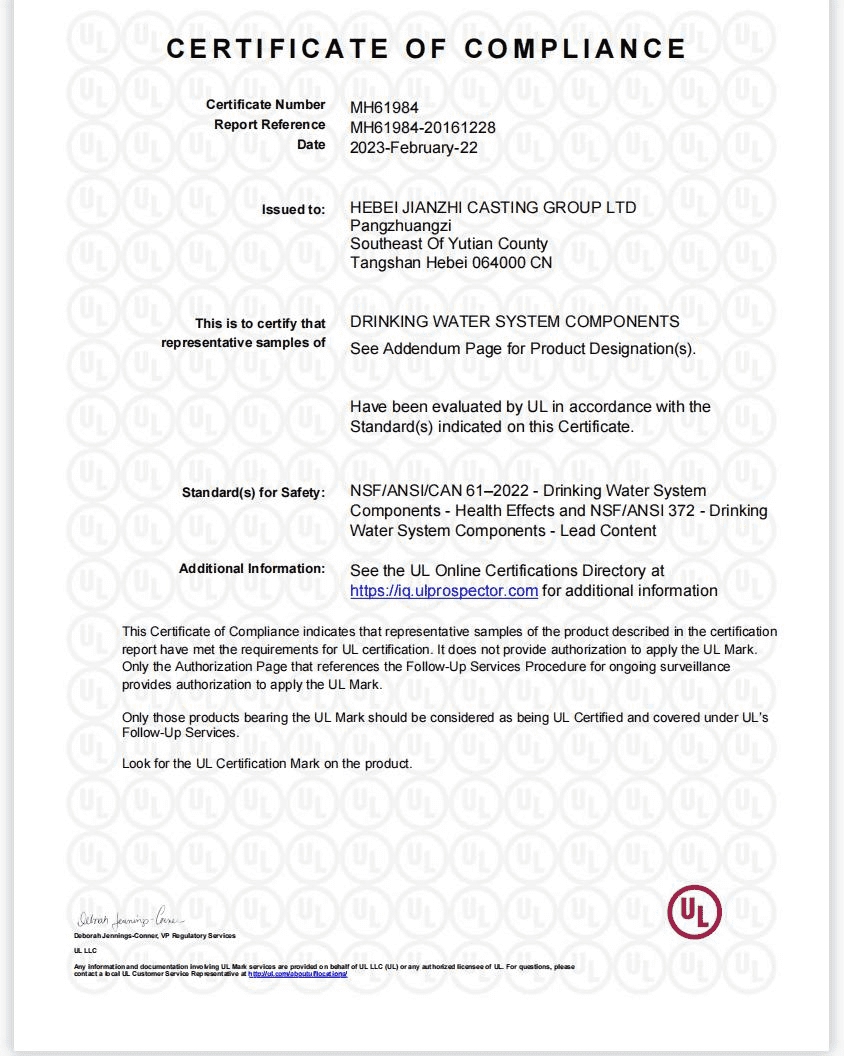

Certificate of the product

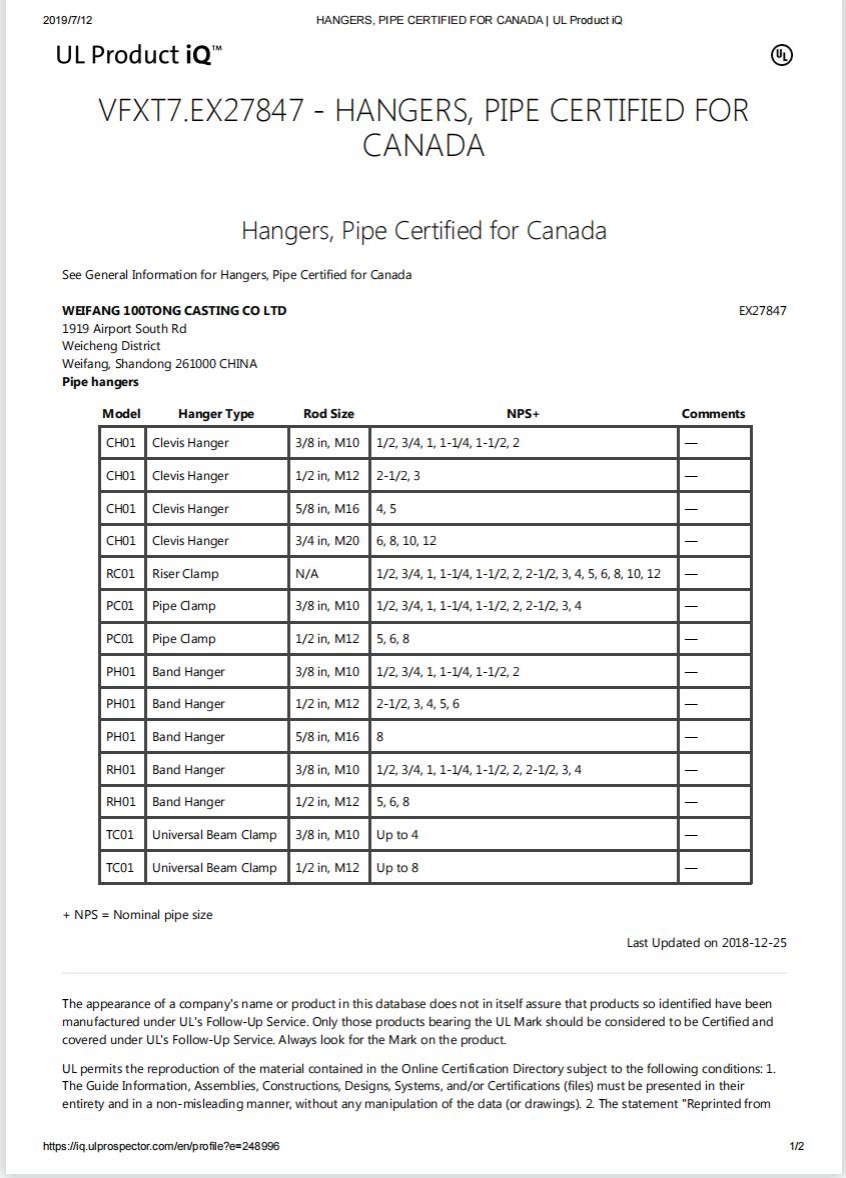

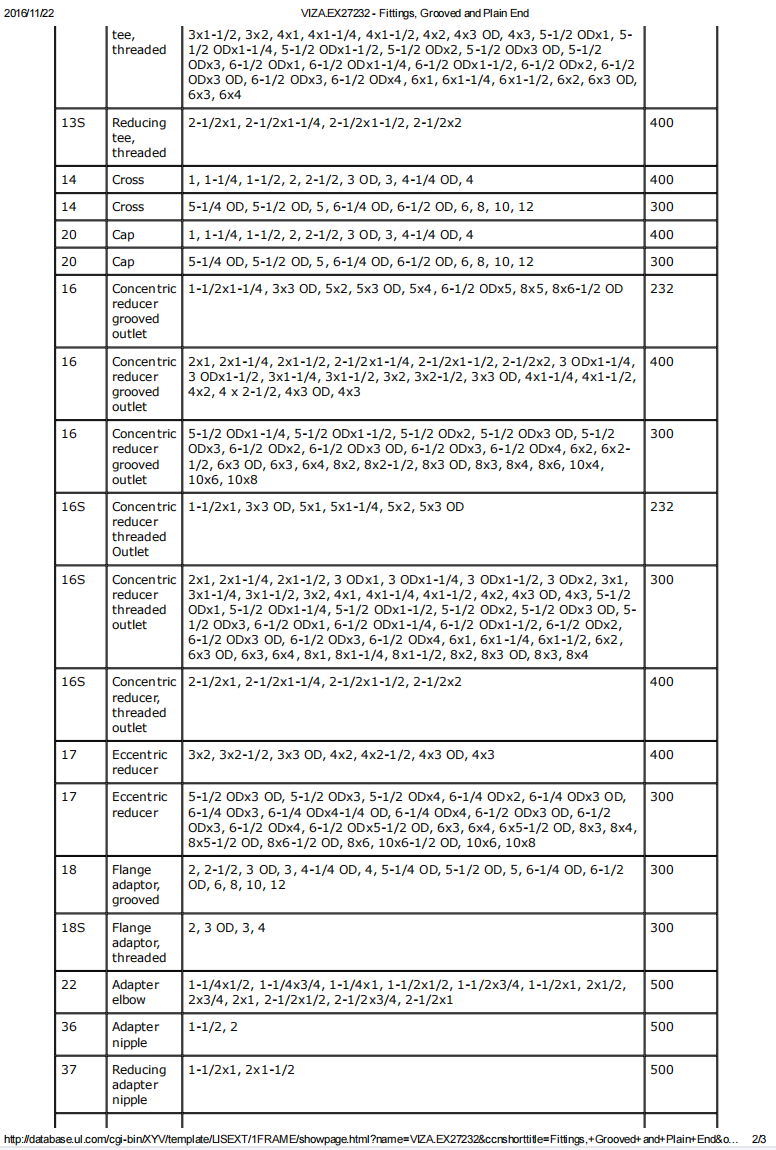

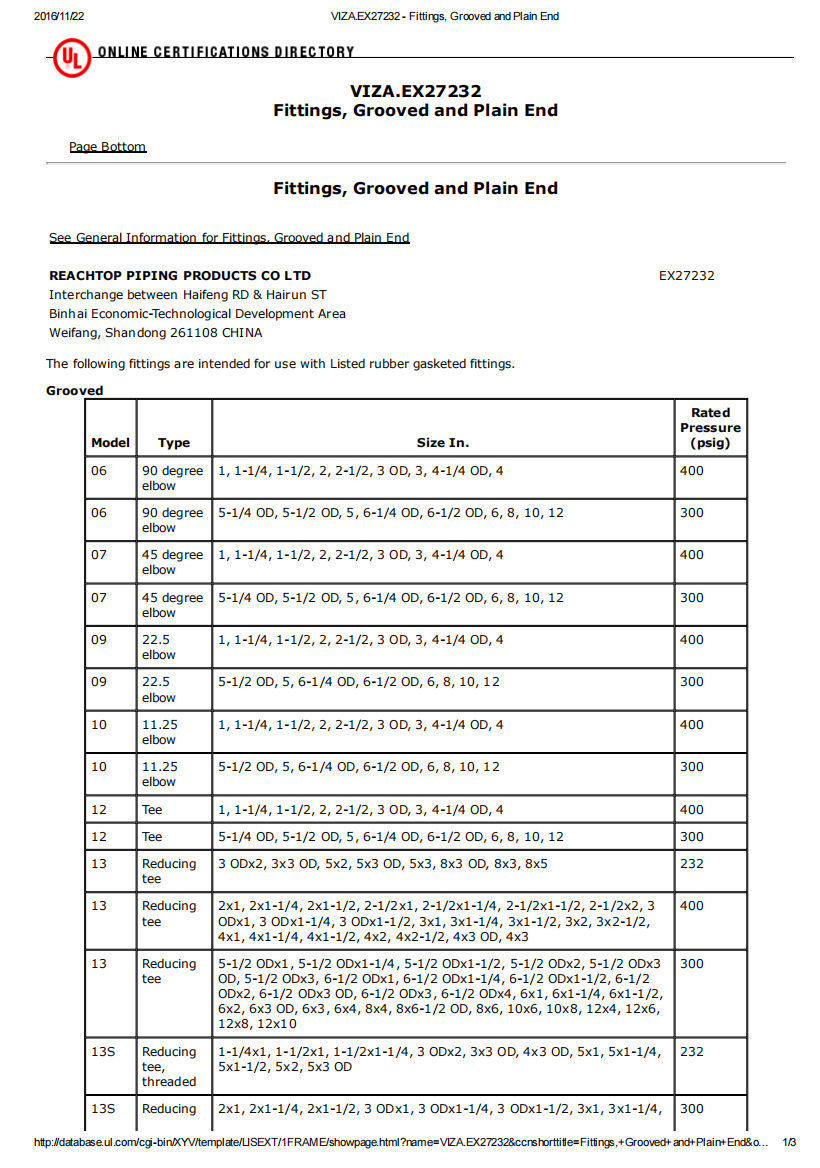

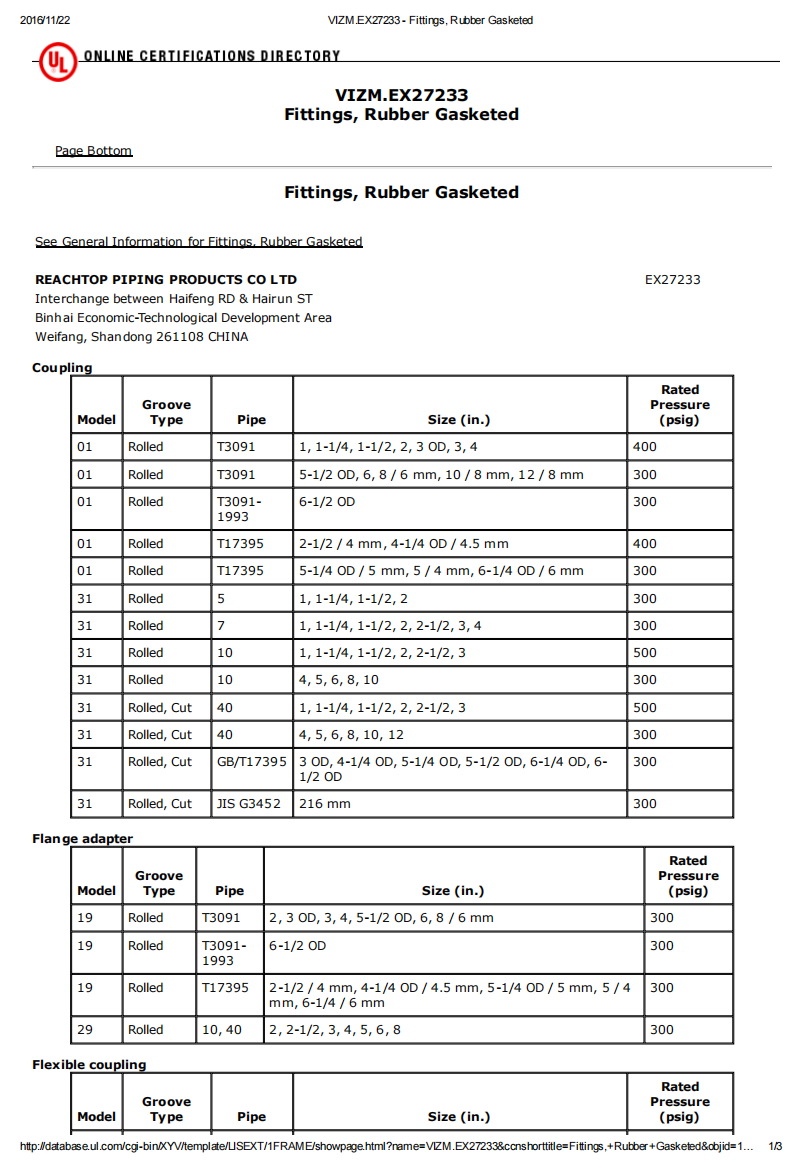

Fluid Tech Group’s products are available in both heavy-duty and medium-sized options. Heavy-duty products have UL/FM, SIRIM, WRAS, ISO, SGS, TUV certification; Medium-sized products fully meet the requirements of quality standards, meet market and engineering requirements, and can meet different types of customer needs.

How do we achieve quality control and excellent service

Professional workers, engineers, sales and after-sales personnel, is the premise of fast delivery, stable quality and fast delivery.

High-precision equipment is quality assurance. Each of Fluid Tech Group’ five production base is equipped with the world’s most advanced DISA D3 production line FONDARC sand mixer. 3800 sets of molds, 24 warehouses, 576 automatic threading machines for product processing. The new annealing technology independently developed and designed makes the success rate of annealing of pipe fittings rank first in China. There are 3 galvanizing workshops and two painting workshops, which are hot-dip galvanizing, electro-galvanizing and red epoxy, blue epoxy surface treatment products. The thickness of the zinc layer of hot-dip galvanized pipe fittings is greater than 70um, which meets the AST M A153 galvanized standard. The thickness of the electro-galvanized zinc layer is greater than 35um.

Quality testing facilities include: spectrometer, carbon and sulfur analyzer, meta-sulfur analyzer microscope, tensile strength testing equipment, pressure testing equipment, adhesion testing equipment, coordinate measuring machine, hardness tester, etc. The products are 100% inspected to ensure that the quality is qualified before leaving the factory.