Main Product

About

COMPANY PROFILE

Fluid Tech Group is the first comprehensive export company specializing in fire protection, waterworks system, plumbing, hardware products, and HVAC industry products in the North of China. In 2018, Combined with a number of foundry factories and machinery processing factories, Fluid Tech Pipeline System ( Tianjin) Co., Ltd. was established in Tianjin. Fluid Tech not only provides one-stop procurement of pipeling systems products, but also meets customers’ customized processing products; and provides fluid conveying solutions and consulting services. Fluid Tech Group currently has 5 major production bases to produce products, which arelocated in Tangshan City, Hebei Province, Weifang City, Shandong Province, Cangzhou City,Hebei Province, Shanxi Province and Zhejiang Province. The participating factories have passed ISO, SGS, TUV certification.

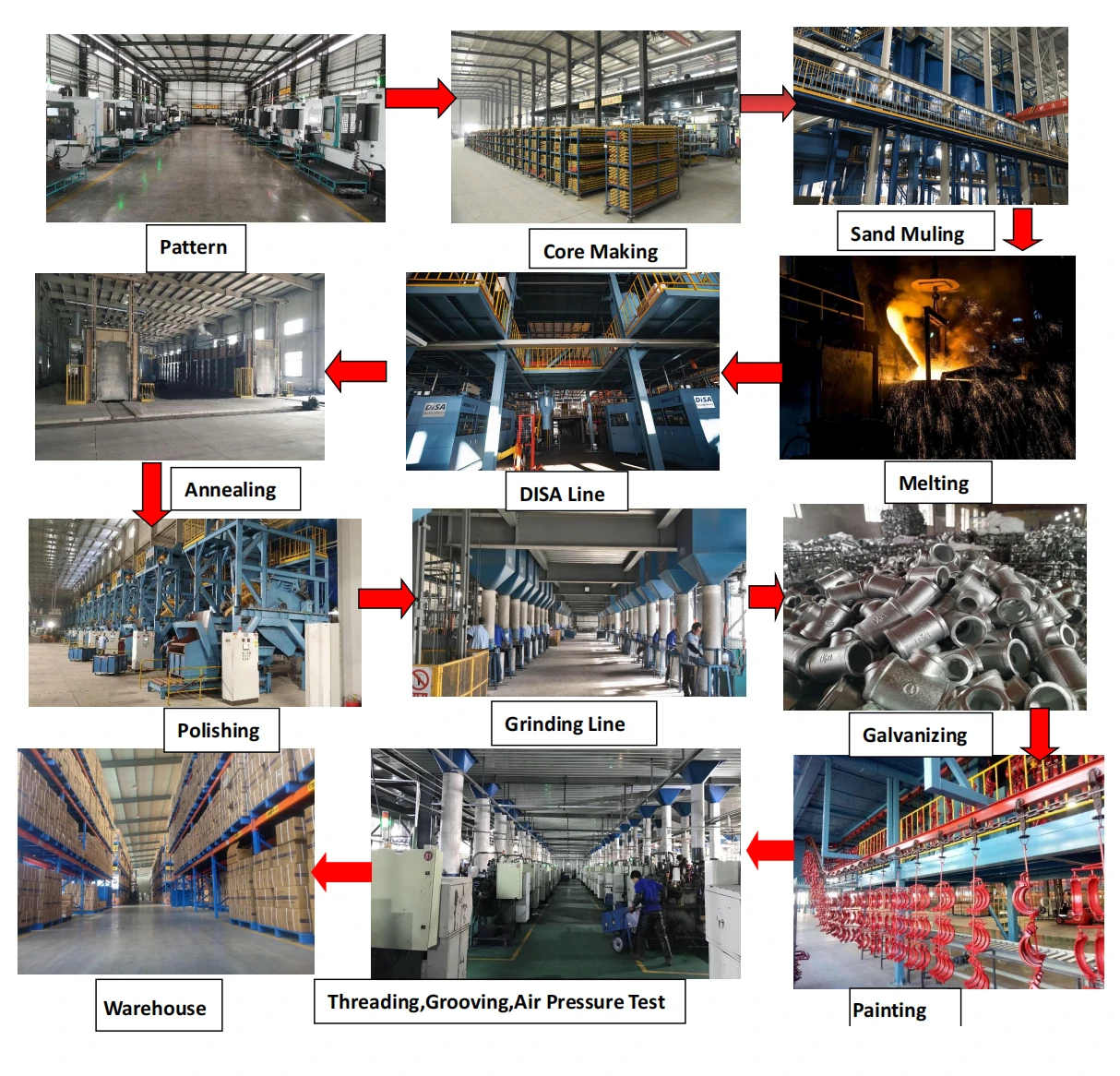

State of the Art Equipment

High precision equipment is quality assurance. Fluid Tech’s 5 produce base are all equipped the world’s most advanced DISA D3 production line, FONDARC sand mixer, to ensure high precision, fast production and delivery. 3,800 sets of molds, 24 warehouses, 576 automatic threading machines for products processing. The tunnel-type annealing technology independently developed and designed makes the annealing success rate of the pipe fittings the first in the industry. There are 3 galvanizing workshopsand two painting workshop where is producing hot-dip galvanized、electro-galvanized and red painting ,blue painting and Epoxy surfacement products. The zinc layer thickness of hot-dip galvanized pipe fittings is more than 70um, which conforms to the ASTM A153 galvanizing standard. The thickness of the zinc layer of electro-galvanizing is more than 35um.

Reliable Quality Assurance

Fluid Tech is honored as the National enterprise technical center and is capable and qualified to conduct full series of tests and inspections including chemical checking, etc. Inspection facilities include:

spectrometer, carbon sulfur analyzer, metallurgical microscope, tensile strengthtesting equipment, pressure testing equipment, adhesive force testing equipment, CMM, hardness tester,etc.From incoming inspection to finished product, quality is checked and monitored in the whole process. Each step of the manufacturing process is carefully documented, regularly reviewed for revision control and updating standard. Quality procedures are constantly monitored and updated to assure that only the highest and most consistent quality products are supplied to our valued customers.

Welcome to Fluid Tech

news

cases

Grooved Tee, Grooved Cross, and Grooved Reducer Make Installation Super Easy!

Grooved fittings play a vital role in piping systems, offering a secure, efficient, and flexible...

Building Robust Piping Networks: Malleable Iron Fittings and the Power of Galvanization

Constructing Enduring Piping Infrastructures with Malleable Iron Fittings The backbone of any...