Fire Protection Systems

As a leading manufacturer and supplier of fire valves in China, FLUID-TECH takes pride in offering a comprehensive range of high-quality pipe fittings at competitive wholesale prices. Our unwavering commitment to excellence and customer satisfaction drives us to consistently provide reliable and durable products that meet industry standards and surpass expectations.

Fire valves are specialized valves used in fire protection systems to control the flow of water or other fire suppression agents. They are designed to open automatically when exposed to heat or fire and close after use.

Main Types Of Fire Protection Valves:

- Control valves – Used to regulate the flow of water into fire sprinkler systems. They can be adjusted to provide the proper water pressure.

- Check valves – Prevent backward flow in fire sprinkler pipes. They only allow flow in one direction towards the sprinkler heads.

- Deluge valves – Open when exposed to elevated temperatures to allow large flows of water into deluge sprinkler systems.

- Hose valves – Provide access to fire hoses from fire water supply pipes. They typically have external handles for manual operation.

- Post indicator valves (PIVs) – Identify the location of the main shutoff valve for a fire sprinkler zone. They have external handles and visual indicators.

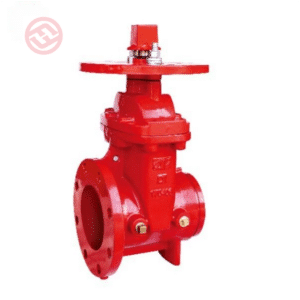

- OS&Y valves (outside screw and yoke) – A type of gate valve commonly used as a PIV. They have bronze or cast iron bodies with resilient wedge gates.

Fluid Tech Group – Professional To Manufacturing In Fire Valves

For over 20 years, Fluid Tech Group has built its reputation as a leading manufacturer and supplier of high-quality types of fire sprinkler valves in China. We focus on engineering reliable Fire Valves solutions to ensure safety and performance in the most demanding industrial applications. There are many types of fire valves produced by us. It such as Deluge alarm valves, Flanged globe type pressure reducing valves, Grooved Y-type strainer, Resilient seated OS&Y type flange gate valve, Resilient seated flanged ends swing check valves and Floating ball valves, etc. Additionally, we will list main specifications of typical fire vlaves, so that you may choose conveniently.

Deluge Alarm Valve:

- Sizes:

50 mm (2 inches) to 300 mm (12 inches) diameter - Material:

Ductile iron conforming to ASTM A536 Grade 65-45-12 standard - Dimensions:

According to GB 5135.5 (Chinese standard) and BS EN 558 (European standard) - Connections:

Complying with BS EN 1092-2 flanged connection standard - Pressure Rating:

PN10 (10 bar/145 PSI)

PN16 (16 bar/232 PSI) - Surface Treatment:

According to ANSI/AWWA C550 standard

Grooved Y-Type Strainer:

- Sizes:

50 mm (2 inches) to 400 mm (16 inches) diameter - Material:

Ductile iron conforming to ASTM A536 Grade 65-45-12 standard - Dimensions:

According to ASME B16.42 standard - Connections:

Comply with ASME B16.1 Class 125/250 flanged connection standards - Pressure Ratings:

Available in 300 PSI, 250 PSI and 200 PSI pressure ratings - Temperature Range:

Suitable for use from 0 to 200 degrees Celsius - Surface Treatment:

Per ANSI/AWWA C550 standard - Certifications:

UL Listed

FM Approved

Resilient Seated OS&Y Type Flange Gate Valve:

- Sizes:

50 mm (2 inches) to 600 mm (24 inches) diameter - Material:

Ductile iron conforming to ASTM A536 Grade 65-45-12 standard - Dimensions:

According to AWWA C515 and ASME B16.10 standards - Connections:

Comply with ASME B16.1 flanged connection standards - Pressure Ratings:

Available pressure ratings include 300 PSI, 250 PSI and 200 PSI - Temperature Range:

Suitable for use from 0 to 80 degrees Celsius - Surface Treatment:

Per ANSI/AWWA C550 standard - Certifications:

UL Listed

FM Approved

We invite you to contact us to discuss wholesale prices on our fire valves. Our sales team is available to provide price list and explore potential avenues for collaboration. In addition to direct sales, we maintain a robust OEM program for customers seeking private labeling opportunities. Regardless of your production needs, FLUID-TECH’s knowledgeable representatives can support your goals through customized solutions and exceptional partnership.