Fire Protection Grooved Butterfly Valve

Code:D81X4

Size: 2″-12”(DN50-DN300)

Material: Ductile iron ASTM A536, 65-45-12

Dimension: MSS SP-67

Connection:AWWA C606-2006 Grooved and Shouldered Joints

Pressure Rating: 175PSI, 200PSI, 250PSI, 300PSI

Temperature: 0-80 ℃

Surface Treatment: ANSI/AWWA C550

Certificate: UL Listed / FM Approved

Medium: Water, gas etc.

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

What is the Fire Protection Grooved Butterfly Valve?

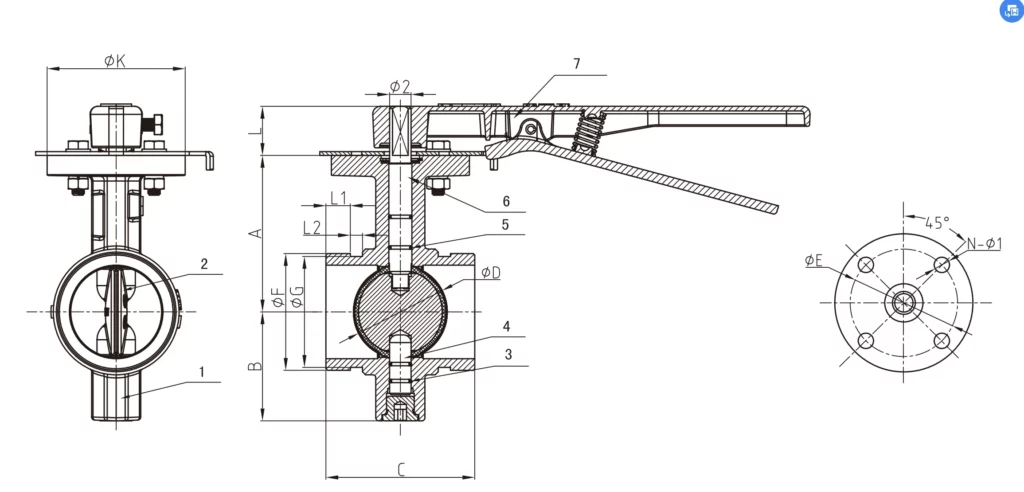

Grooved butterfly valve (Gear actuator & tamper switch) is light weight valve with signal gearbox, and it is grooved connection. The valve is fully open or closed when the disc is rotated a quarter turn.The Grooved signal butterfly valve is a grooved clamp connection valve designed completely based on the principle of symmetry. It is symmetrical in the axial centerline, radially centerline, two-way full pressure seal, with a signal device, which can give the valve action. It is mainly used in various pipelines of water supply and drainage, building fire protection and other systems, especially in fire protection pipelines, to cut off and adjust the flow of the medium.

Product Drawing

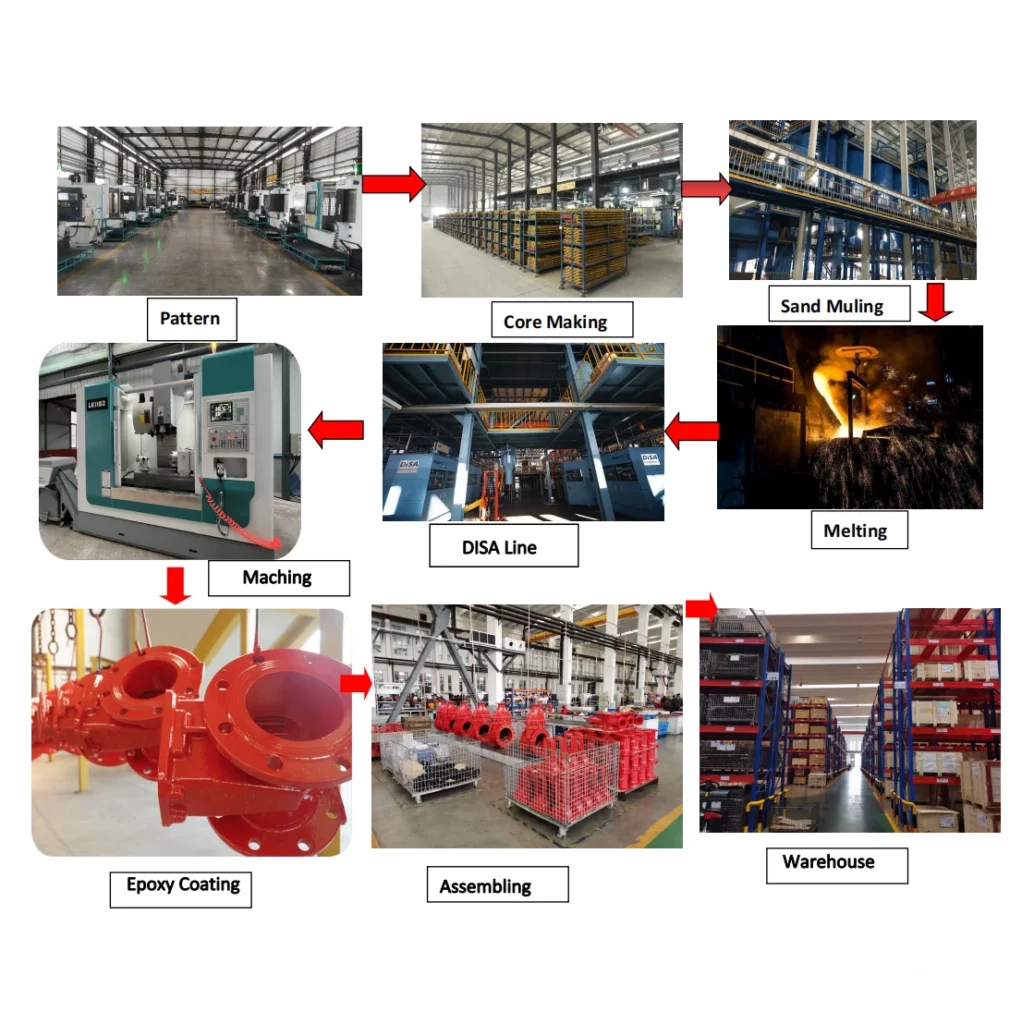

Quality Control

Advanced equipment guarantee the production of high quality products.

Advantages of DISA moulding line:1. High quality precise casting less scrap and lower finishing costs. 2.High Production Efficiency(1)Fast production: 350 moulds per hour, pattern changing time cut down to 2-3 minutes

(2).higher profitability over a longer service life. 3. Safety and Environmental Friendly safe, easy and clean operation (CE and ISO 14001 compliant)

High-precision, hydraulicly driven mould transport,no shifting, distortion, ordisplacement of moulds.

The advantage of the sand supply system:The sand supply system is from the best class sand processing equipment manufacturers of China, with straight structure, easier maintenance, environmently friendly, high degree of automation, high safety factor, good parameters of sand stability.

Fluid Tech is honored as the National enterprise technical center and is capable and qualified to conduct full series of tests and inspections including chemical checking, etc. Inspection facilities include:spectrometer, carbon sulfur analyzer, metallurgical microscope, tensile strength testing equipment, pressure testing equipment, adhesive force testing equipment, CMM, hardness tester, etc.From incoming inspection to finished product, quality is checked a

nd monitored in the whole process. Each step of the manufacturing process is carefully documented, regularly reviewed for revision control and updatin

g standard. Quality procedures are constantly monitored and updated to assure that only the highestand most consistent quality products are supplied to our valued customers.

Application and Case

Fire Protection Grooved Butterfly Valve are used in fire protection system, water system, gas system, irrigation system, etc.Fire Protection Butterfly Valves are used in many projects , such as China Taiwanese Building 101, Xiamen Building,Wuhan Expo Building and other famous landmark projects.