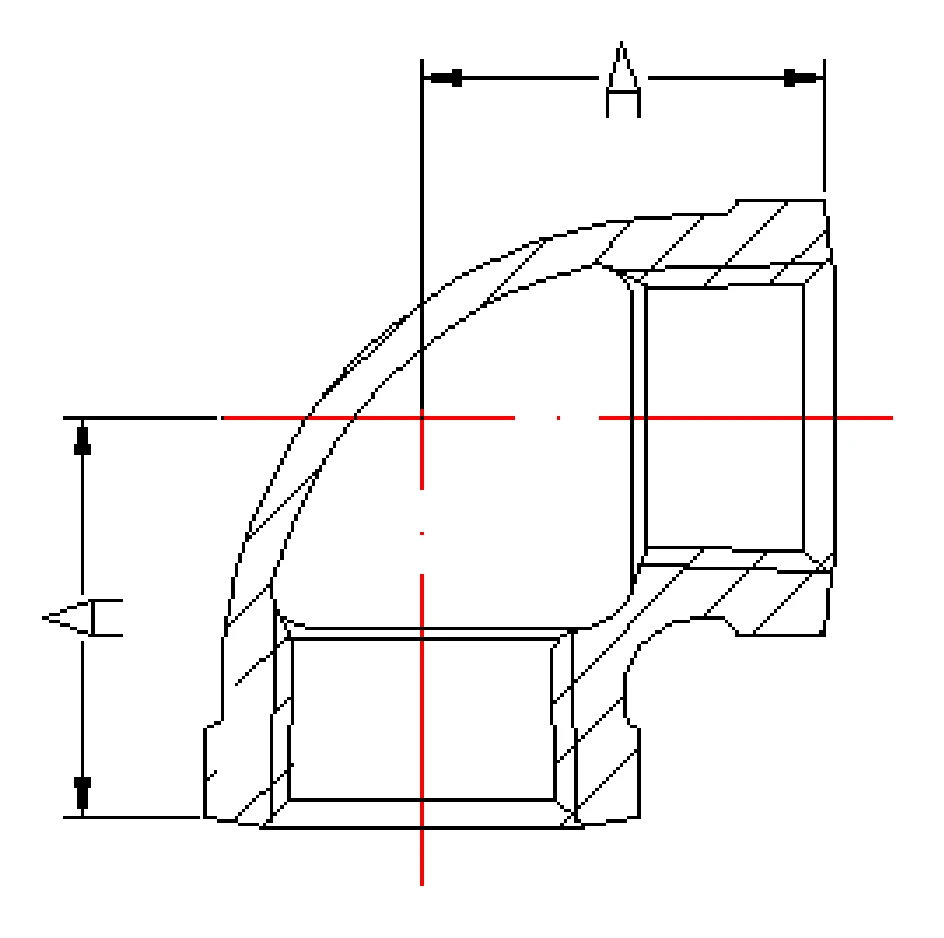

Malleable Iron 90 90° Elbow BSPT Thread

Code:90

Size: 1/8”-6”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron pipe fittings 90 90° Elbow. Elbow is a kind of connection pipe fittings commonly used in plumbing installation,Fire Protection, Waterworks, HVAC,Plumbing,GAS,Irrigation,or other piping systems. It is used for the connection of pipe bends and is used to change the direction of the pipeline. According to the production process, it can be divided into: welding elbow, forged elbow, push elbow, casting elbow, butt welding elbow, etc. Malleable Iron pipe fitting elbow is a kind of casting elbow, through melting, annealing, and then machined into pipe fittings. This material pipe fittings have good malleable castability, are relatively easy to process, and have a certain strength. Fittings are used in piping systems with working pressures between 1.6MPa to 2.5MPa. The connection of the piping system is connected by threads, and the threaded connections are sealed with pipe thread seal tape or sealant. There are three ways of surface treatment of pipe fittings: hot-dip galvanizing, electro-galvanizing and black. Galvanizing can make the pipe fittings have good anti-rust, anti-corrosion and other properties. Hot-dip galvanizing is done by placing the pipe filigents in the melted zinc liquid, and the thickness of the zinc layer is relatively thick, which can reach more than 70um. Electro galvanizing, also known as cold galvanizing, is to put the zinc block in the electrolyte, and then through electrostatic adsorption to make zinc ions attach to the surface of the pipe fittings, the thickness of the zinc layer is uniform, but the thickness of the zinc layer is thin, the thickness is more than 25um.

Product Drawing

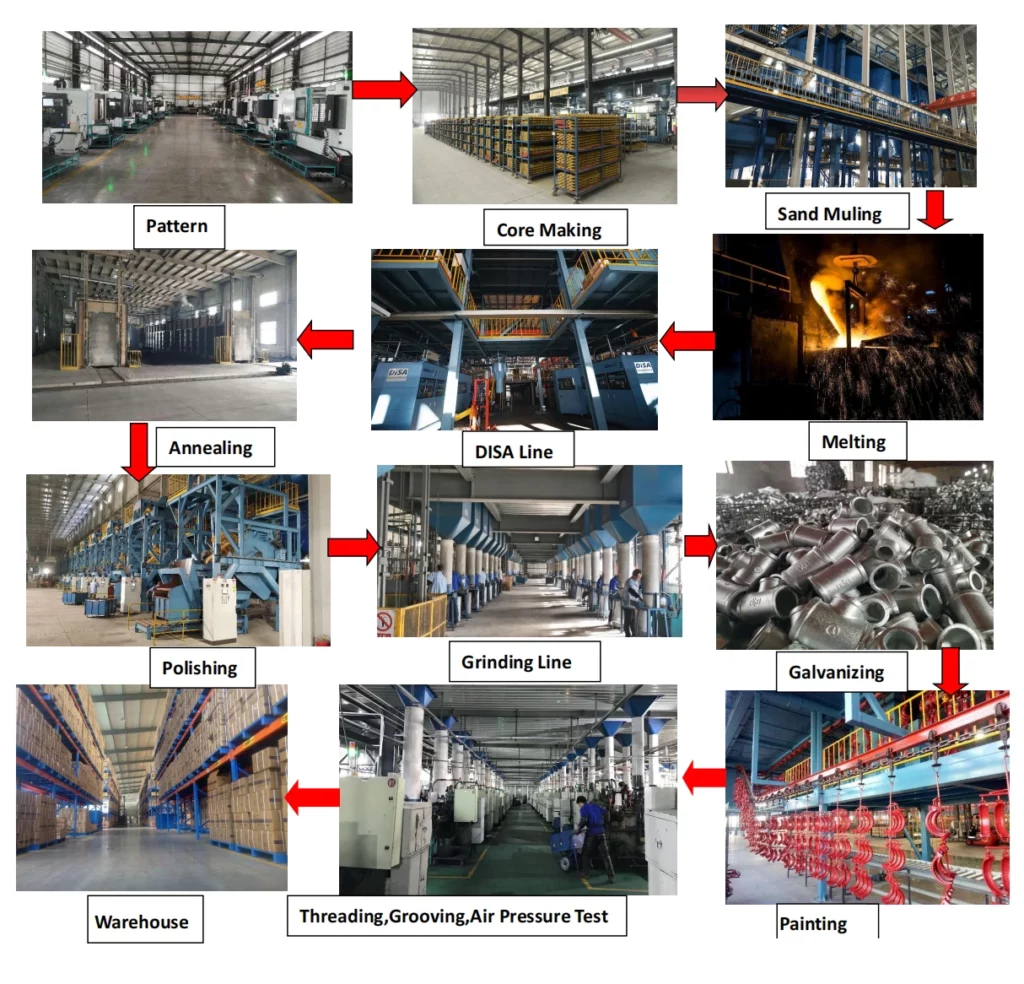

Quality Control

Fluid Tech is honored as the National enterprise technical center and is capable and qualified to conduct full series of tests and inspections including chemical checking, etc. Inspection facilities include:spectrometer, carbon sulfur analyzer, metallurgical microscope, tensile strength testing equipment, pressure testing equipment, adhesive force testing equipment, CMM, hardness tester, etc.From incoming inspection to finished product, quality is checked and monitored in the whole process. Each step of the manufacturing process is carefully documented, regularly reviewed for revision control and updating standard. Quality procedures are constantly monitored and updated to assure that only the highestand most consistent quality products are supplied to our valued customers.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.