Grooved Cross

Code:XGQT12

Size: 1”-12”(DN25-DN300)

Material: Ductile iron ASTM A536, 65-45-12

Dimension: ISO6182、AWWA C606、GB 5135.11

Connection:ASME B36.10、ASTM A53-A53M、ISO 4200

Thread: If have ISO 7-1,BS 21,BSPT, NPT,ASME B1.20.1

Pressure Rating: 175PSI-500PSI

Surface Treatment: Red Painting,Epoxy Coating ,Hot-Dip Galvanized,Electroplated

Bolt & nut: ASTM A449/ CLASS 8.8/ ISO 898

Gasket: EPDM, Nitrile, Silicone rubber, etc.

Certificate: UL Listed / FM Approved

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

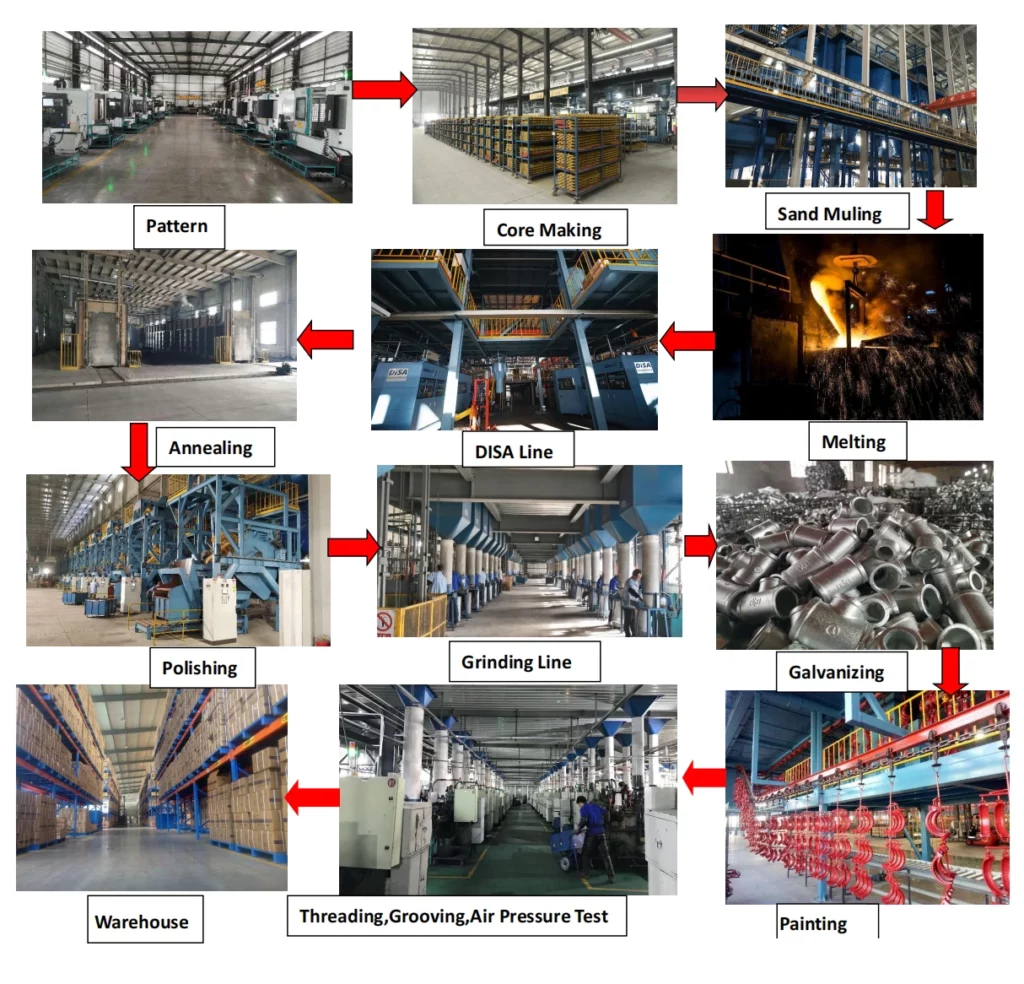

Product Description

Products Details

Ductile iron Grooved pipe fittings Equal Tee. The material is ductile iron.The connect method is Grooved connection. The Grooved Tee also called DI Grooved tee. Grooved Tee have Grooved tee short,Grooved tee long radius 90 degree. Grooved Reducing Tee,Grooved tee with Thread outlet,also called Thread Grooved Tee,normaly the branch outlet is thread end ,the main outlet is Grooved end. According to the surface coating ,dip painting Grooved Tee red color ,epoxy red color Grooved Tee ,epoxy blue color Tee ,galvanized Grooved tee.

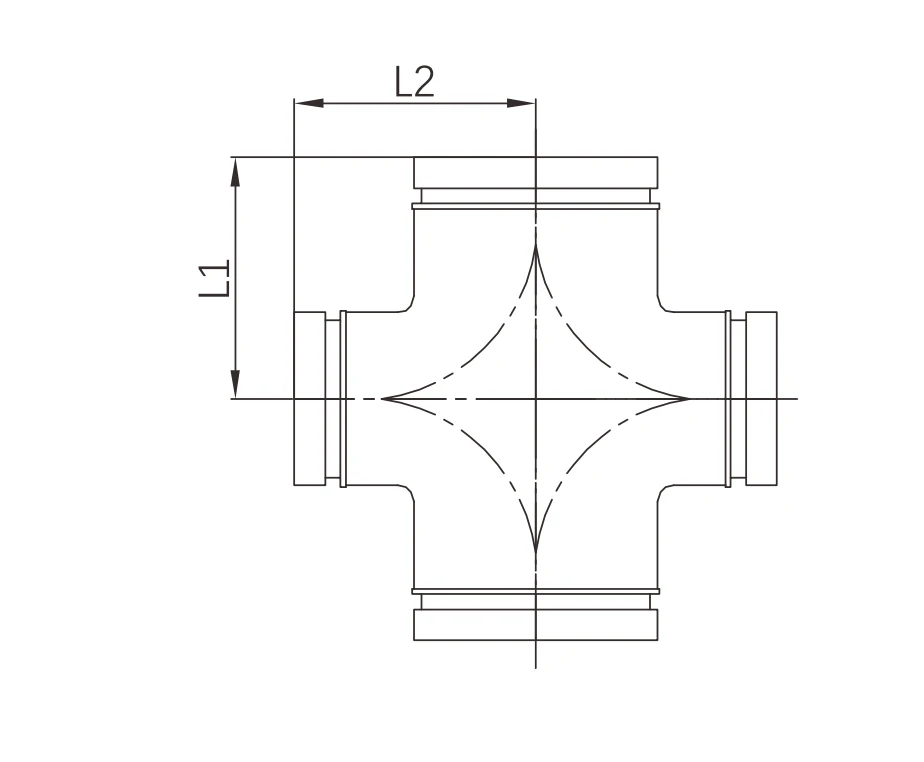

Product Drawing

Grooved pipe surface requirements

The surface of grooved pipe fittings should be flat and smooth, and defects such as pores, sand holes, slag inclusions, cold partitions, shrinkage holes, cracks, and depressions that affect the performance are not allowed. There are no defects such as bulges and depressions in the casting groove. There are no processing defects and bump damage in the processing parts of grooved pipe fittings. The logo is clearly recognizable.

The surface of grooved pipe fittings should be treated with anti-corrosion treatment by dipping paint, spraying, hot-dip galvanizing, etc.:

a) Paint layer. It should be uniform, smooth and firm, without lacquer tumor, paint accumulation and paint leakage, the thickness of the paint layer is not less than 25.4μm, and the lead content of the paint layer is less than 0.009%.

b) Plastic layer. It should be uniform, continuous, smooth and firm, and should not be flammable when applied to fire protection systems. The thickness of the plastic layer is not less than 40μm.

c) Hot-dip galvanized layer. The zinc layer on the surface of galvanized groove pipe fittings should be uniform and continuous smooth, and there should be no defects such as zinc leakage, zinc layer falling off, and black spots; The contact surface with the rubber ring/pad is not allowed to have appendages such as zinc tumor, zinc slag, pile zinc, etc., and the lead content of the zinc layer is not more than 0.1%. The minimum zinc layer thickness is 63 μm.

Bolts and nuts should be hot-dip galvanized, electro-galvanized and other anti-corrosion treatments:

a) Electrogalvanizing. The electroplating layer has a bright luster, and the zinc layer is uniform and complete, there must be no zinc leakage and rust spots locally, and the thickness of the zinc layer is not less than 8μm.

b) Hot dip galvanizing. Hot-dip galvanizing should comply with the provisions in GB/T5267.3, the surface should be smooth, no leakage plating surface, zinc tumor, black spots, no residual solvent residue, oxide scale inclusions and other defects that damage the intended performance of parts. The thickness of the zinc layer is not less than 40μm.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as China Taiwanese Building 101, Xiamen Building,Wuhan Expo Building and other famous landmark projects.