Grooved Flexible Coupling

Code:XGQT02

Size: 1”-16”(DN25-DN400)

Material: Ductile iron ASTM A536, 65-45-12

Dimension: ISO6182、AWWA C606、GB 5135.11

Connection:ASME B36.10、ASTM A53-A53M、ISO 4200

Thread: If have ISO 7-1,BS 21,BSPT, NPT,ASME B1.20.1

Pressure Rating: 175PSI-500PSI

Surface Treatment: Red Painting,Epoxy Coating ,Hot-Dip Galvanized,Electroplated

Bolt & nut: ASTM A449/ CLASS 8.8/ ISO 898

Gasket: EPDM, Nitrile, Silicone rubber, etc.

Certificate: UL Listed / FM Approved

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Grooved fittings are a new type of steel pipe connection fittings, also called clamp connections, which have many advantages. The design specification for automatic sprinkler system proposes that the connection of system pipes should adopt grooved connectors or threaded, flanged connections; pipes with a diameter equal to or greater than 100mm in the system should use flanges or grooved connectors in sections connect.

Grooved fittings include two broad categories of products:①The pipe fittings that play the role of connection and sealing include rigid joints, flexible joints, mechanical tees and grooved flanges; ②The pipe fittings that play the role of connection transition include elbows, tees, crosses, reducers, blind plates, etc.

The grooved connection pipe fittings used for connection and sealing are mainly composed of three parts: sealing rubber ring, clamp and locking bolt. The rubber sealing ring on the inner layer is placed on the outside of the pipe to be connected, and matches the pre-rolled groove, then buckle the clamp on the outside of the rubber ring, and then fasten it with two bolts. Due to the unique sealable structural design of the rubber sealing ring and the hoop, the grooved joint has good sealing performance, and the sealing performance is enhanced correspondingly with the increase of the fluid pressure in the pipe.

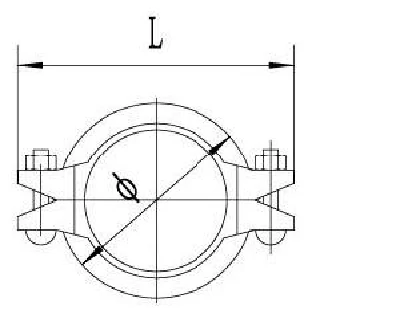

Product Drawing

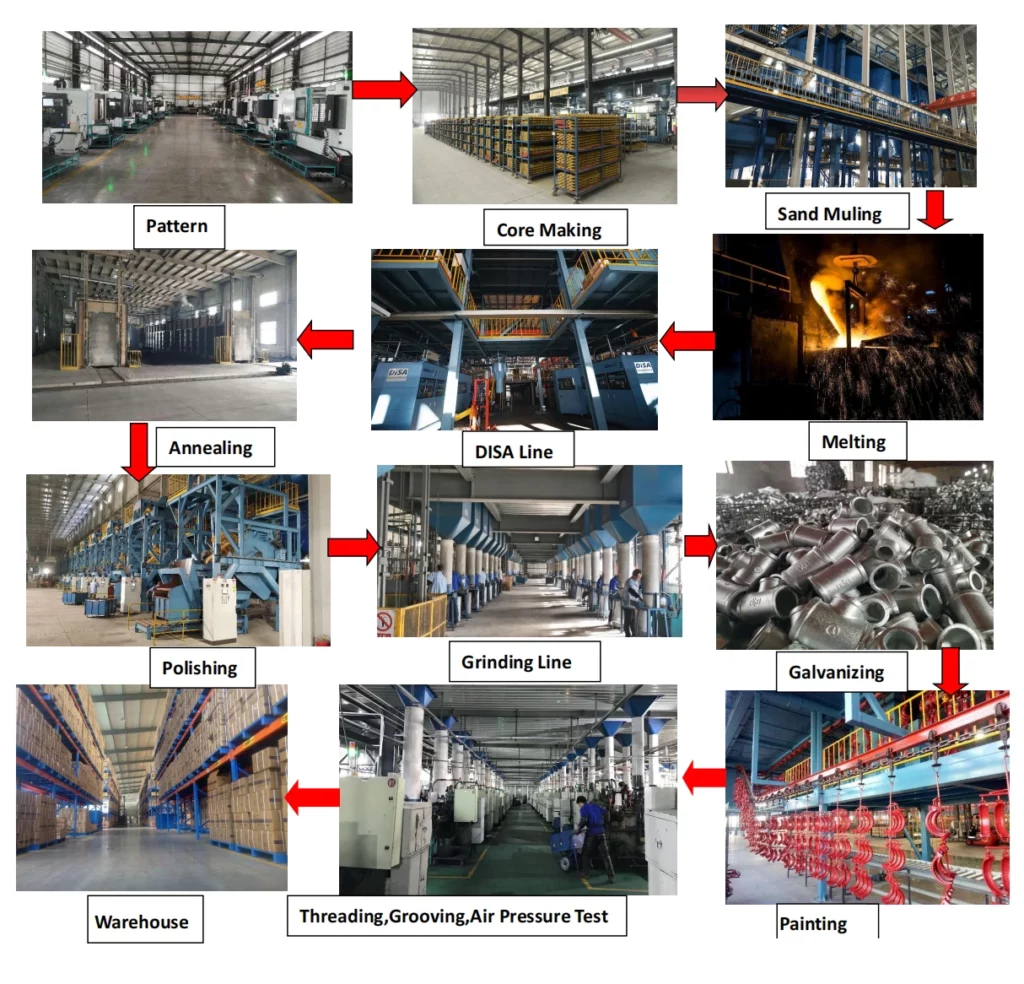

Quality Control:

what is the rigid and flexible Coupling difference?

Coupling play an important role in connecting pipe segments to prevent leaks caused by damaged or damaged joints while maintaining the integrity of the pipe in the process. It is a very suitable fitting for the pipe and pipe industry. Most pipe installations require multiple pipe sections to be joined together or cut to facilitate changing direction and traversing obstacles. A fitting is a concise pipe or pipe. It has a socket or female thread at one or both ends. Fitting allows two pipes or pipes of the same or different sizes to be joined together to form a long pipe.

Flexible coupling

Flexible couplings are designed to transmit torque while allowing some radial, axial and angular misalignment. They can accommodate angular misalignment of up to a few degrees and some parallel misalignment. Elastic couplings allow for some angular misalignment and axial movement, meaning they can be used to create smooth bends and absorb thermal expansion contractions in piping systems. In some cases, the use of elastic couplings can even exclude conventional expansion joints, loops and other expansion devices from the system entirely. When assembling a stretch rubber gasket, the gasket is slightly smaller than the pipe diameter at both pipe ends and produces the first seal. The two halves of the coupling are then placed around the washers that adapt to them. The coupling halves are bolted together to further improve the seal.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as China Taiwanese Building 101, Xiamen Building,Wuhan Expo Building and other famous landmark projects.

Please click, If you consider more detailed information

Please click,If you need to install the tutorial