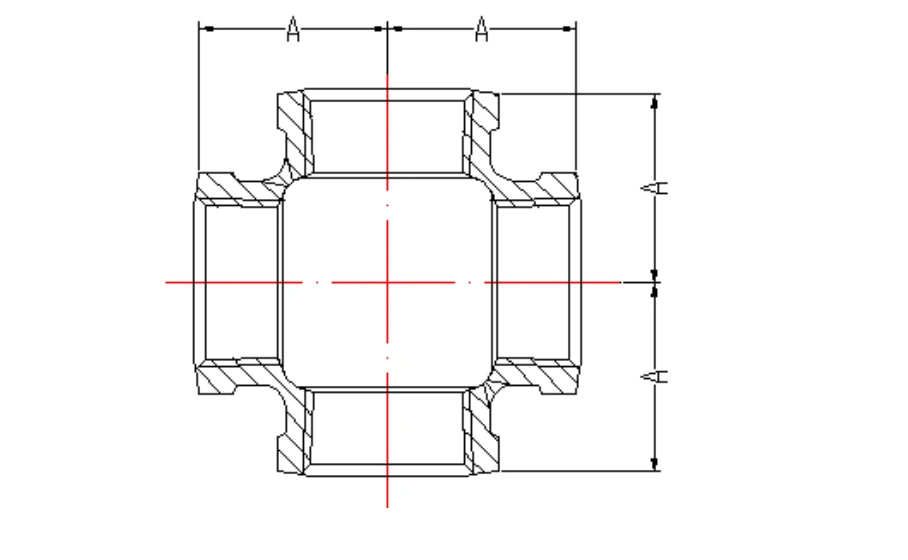

Malleable Iron 180 Cross NPT Thread

Code:180

Size: 1/2”-4”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment: Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

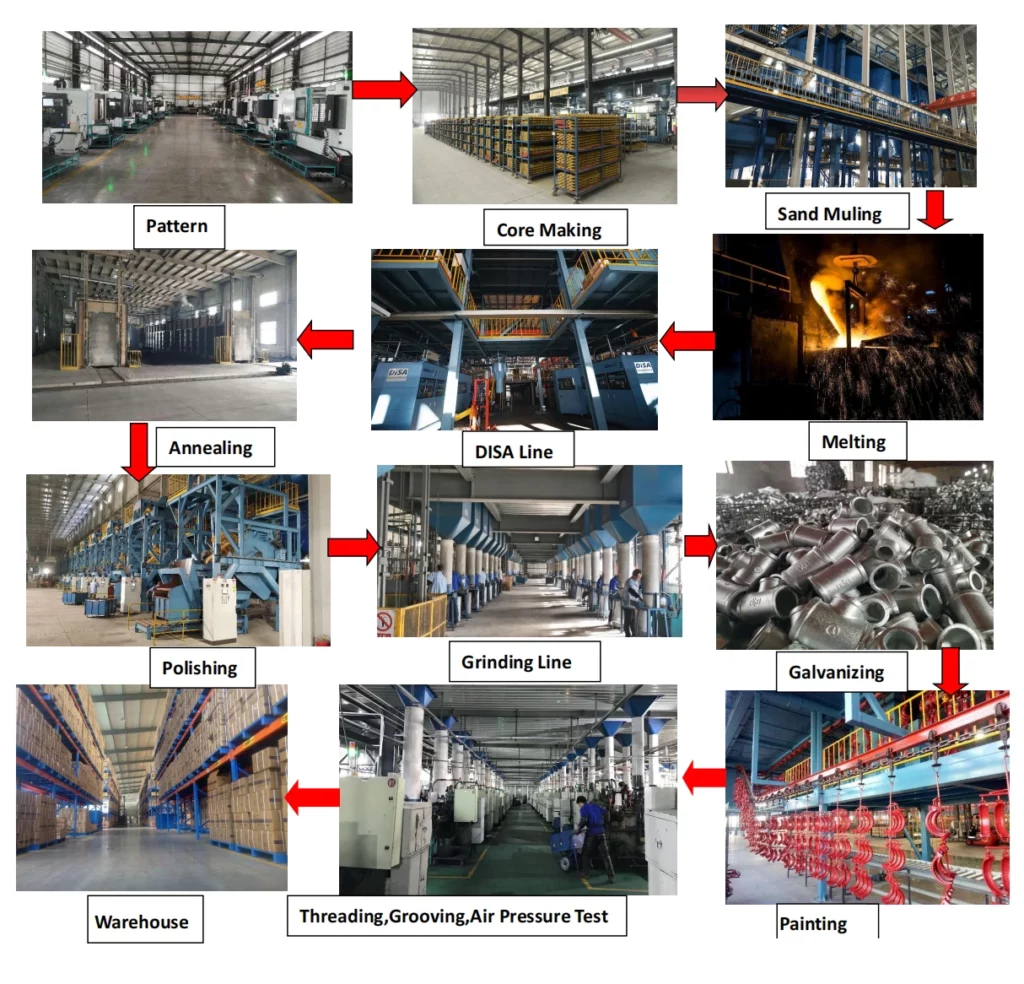

Product Description

Products Details

Black pipe crossings are fittings that control the fluid or gas to be transported in all directions. The 180 four-way fitting provided by Fluid Tech is an equal-diameter four-way fitting, which means that the diameter of the four outlets is the same.

Fluid Tech offers 180 4-way black fittings made of malleable cast iron and connected by pipe threads. The pressure capacity can reach 2.5MPa.

The surface treatment is natural black with good appearance and performance. Sizes from 1/2 inch to 4 inch.

Black tube cross fittings are one of the most commonly used fittings. We offer them in most buildings, and usually, they require thicker walls and heavyweight to prevent damage to pipe threads in 4 directions.

Product Drawing

How to wholesale pipe fittings:

1. First of all, we must confirm the material standard and thread standard of the pipe fittings. The standards of pipe fittings are American standards, British standards and EU standards.

Types of threads (Chapter 2):

According to the different uses of the thread, it can be divided into:

1, International Metric Thread System:

The thread used by China’s national standard CNS. The top is flat , easy to turn, and the bottom is rounded to increase thread strength. The thread angle is 60 degrees, and the specifications are expressed in M. Metric threads can be divided into two types: coarse teeth and fine teeth. The notation is e.g. M8x1.25. (M: code, 8: nominal diameter, 1.25: pitch).

2, American Standard Thread:

The top and root of the thread are flat, and the strength is better. The thread angle is also 60 degrees, and the specification is expressed in a number of teeth per inch. This thread can be divided into coarse teeth (NC); Fine teeth (NF); Extra fine teeth (NEF) grade 3. Notation such as 1/2-10NC. (1/2: outer diameter; 10: Number of teeth per inch; NC codename).

3, Unified Thread:

Jointly formulated by the United States, the United Kingdom and Canada, it is currently commonly used imperial thread.

The thread angle is also 60 degrees, and the specification is expressed in a number of teeth per inch. This thread can be classified as coarse teeth (UNC); fine teeth (UNF); Extra fine teeth (UNEF). The notation is 1/2-10UNC. (1/2: outer diameter; 10: Number of teeth per inch; UNC Codename)

4, V-shaped thread (Sharp V Thread):

The top and root are pointed, weak in strength, and not often used. The thread angle is 60 degrees.

5, Whitworth Thread:

Thread used in British National Standard. The thread angle is 55 degrees, indicating the symbol “W”.

Suitable for rolling manufacturing. Notation such as W1/2-10. (1/2: outer diameter; 10: Number of teeth per inch; W codename).

6, round thread (Knuckle Thread):

It is the standard thread specified by DIN in Germany. It is suitable for the connection of bulbs and rubber tubes. The denotation symbol is “Rd”.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.