Malleable Iron 130 Equal Tee NPT Thread

Code:130

Size: 1/8”-6”

Material: ASTM A197/A197M

Dimension: ASME B16.3, B16.14

Union Dimension:B16.39

Thread: ASME B1.20.1

Pressure Rating: 363PSI,CLASS150

Surface Treatment: Hot-Dip Galvanized,Electroplated

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

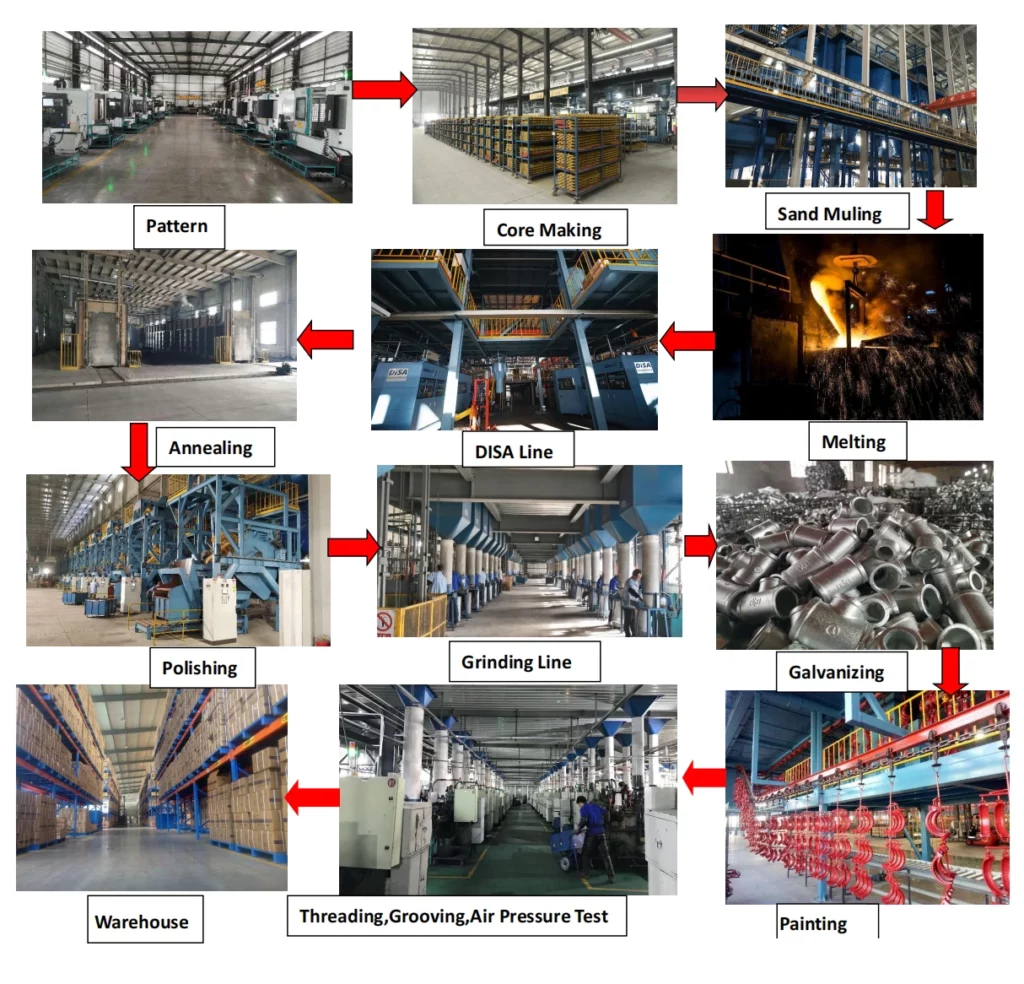

Product Description

Products Details

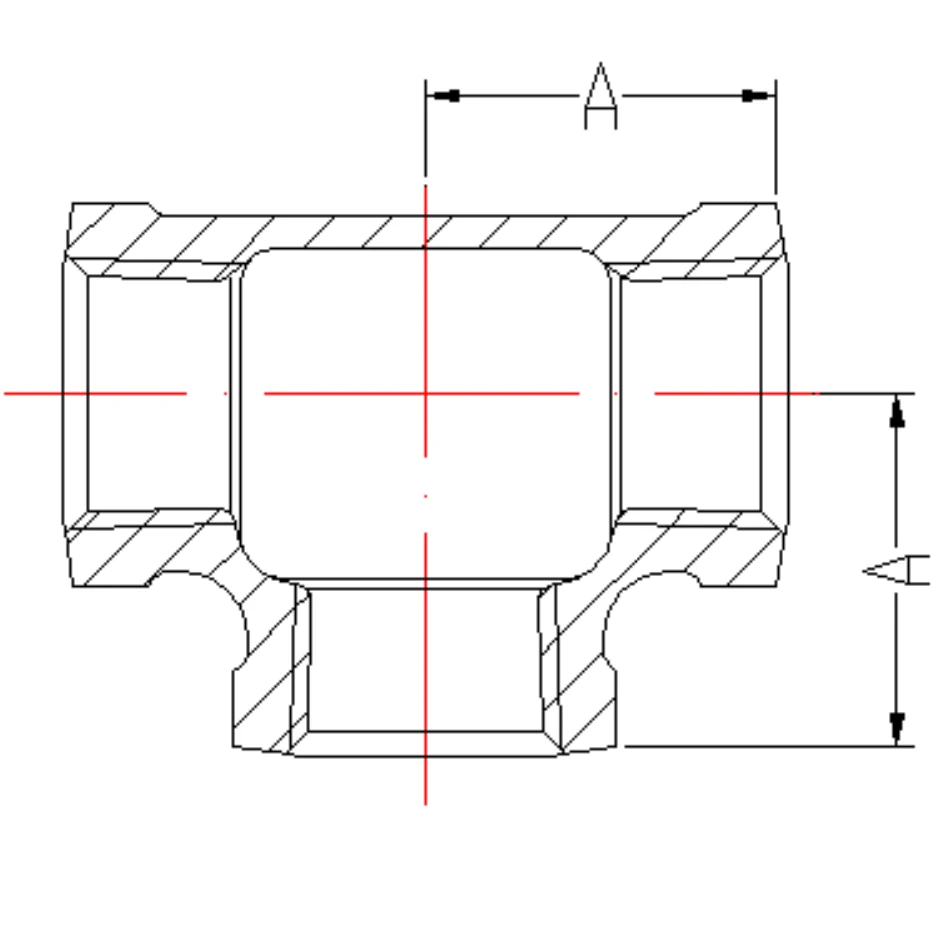

American Standard Malleable Iron pipe fittings 130 Equal Tee . Code is 130. Main outlet and branch outlet is same. We have three type NPT tee,heavy type NPT tee with UL/FM certificate ,medium type NPT tee and light beaded tee. According to the Surface treatment ,hot dip Galvanized tee ,electro plate Galvanized tee or cold Galvanized NPT tee ,and black NPT tee.According to the Threaded Standard,there are have npt Thread tee ,BSp thread tee ,and ISO228 thread tee.If the main outlet and branch outlet is difference. According to different specifications, it can be divided into “equal tee pipe fittings” and “deceleration tee pipe fittings”.Equal tee fittings mean that the diameter of the branch pipe is the same as the diameter of the main pipe.Reduced diameter tee pipe fittings mean that the diameter of the branch pipe is smaller than the diameter of the main pipe, so it is also called unequal diameter tee, and the number of reduced diameter tees is large.

Product Drawing

What is the difference between metric thread,NPT thread, BS thread?

Metric thread generally refers to metric thread, and the unit of measurement of nominal diameter and pitch is in metric units. The imperial US unit of measurement is in imperial units. Taking ordinary threads as an example, the biggest difference between the three lies in the annotation and the units, tolerance bands and tooth angles used, as follows:

1. Metric ordinary thread:

Standard number: GB/T196-2003, etc;Tooth angle: 60 degrees;Unit: mm;Tolerance band: 7H, 6H, 5H, 4h, 6h, 6g…;Thread code: M, coarse teeth and fine teeth can be marked by pitch;Annotation: M20*1.5-6H;(M nominal diameter * pitch – accuracy)

2. NPT thread (uniform thread)

Standard number: ANSI B1.1;Tooth angle: 60 degrees;Unit: inches;Tolerance band: 1B, 2B, 3B…;Thread codes: UNC, UNF, UNEF, UN… Different codes can distinguish the corresponding pitch;Callout: 3/8-16 UNC-2B;(Nominal diameter – number of teeth per inch Thread code – accuracy)

3. BS thread

Standard: BS 84-2007, etc;Tooth angle: 55 degrees;Unit: inches;Tolerance band: 1B, 2B, 3B…;Thread code: BSW, BSF… Different codes can distinguish the corresponding pitch;Calling: 3/8-16 BSW-2B.

The differences between simple summary threads are:

Metric thread, tooth angle 60 degrees.Imperial thread, there are two kinds of straight pipe BSPP, cone tube BSPT, tooth angle 55 degrees.American thread NPT, taper 1:16, tooth angle 60 degrees.Generally, the product will mark the thread standard and size, you can also measure the thread size through the vernier caliper, check the cutting manual and other tables to obtain the corresponding thread, or pass the thread gauge test.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.