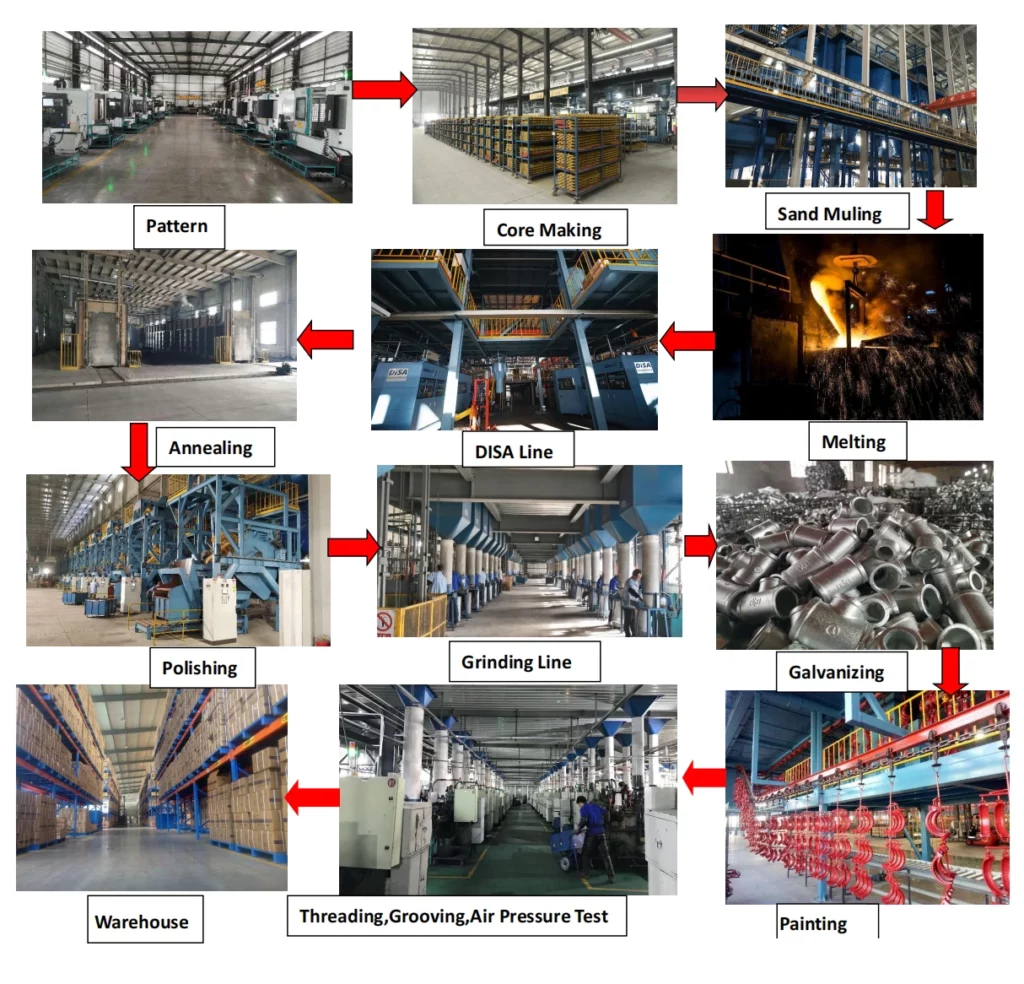

Malleable Iron 220 Equal Socket NPT Thread

Code:220

Size: 1/4”-6”

Material: ASTM A197/A197M

Dimension: ASME B16.3, B16.14

Union Dimension:B16.39

Thread: ASME B1.20.1

Pressure Rating: 363PSI,CLASS150

Surface Treatment: Hot-Dip Galvanized,Electroplated

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

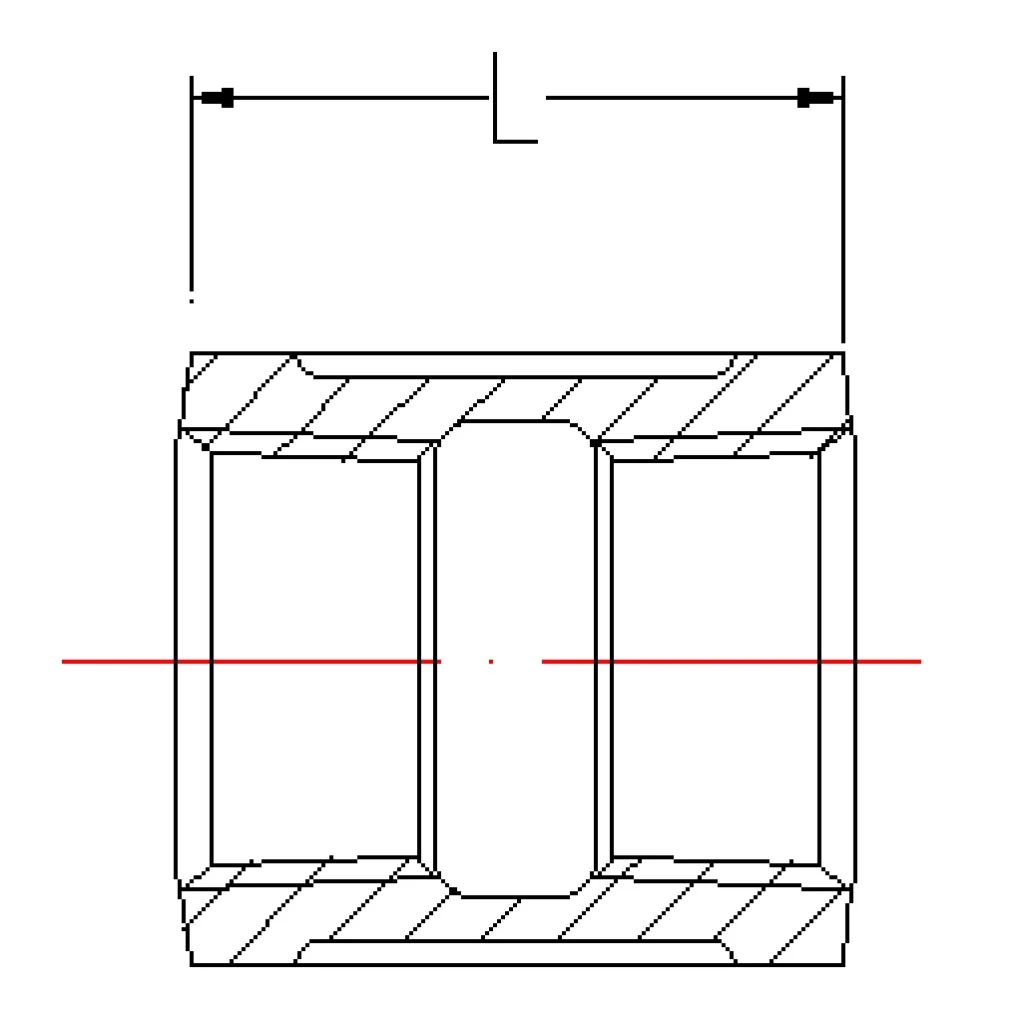

Sockets (Coupling) are often used to connect two pipes of the same size. The socket(coupling) is also called a coupling, malleable cast iron material, the surface can be hot-dip galvanized and cold-galvanized. The 220 socket is partially threaded, with threads at both ends disconnected.Use couplers and sockets to simplify the piping installation process. Designed to glide easily through pipes without additional equipment, they are cemented, welded or mechanically joined to form pressure seal joints.Cast iron threaded elastic couplings for pipes can be fully drilled or incompletely drilled. This is very important for this accessory, as it is mainly used with lock nuts and scrapers. The kit is used as a detachable connection when installing pipes.Cast iron fittings – manufacture of pipe fittings with cylindrical threads. The product material – malleable cast iron – provides high performance, reliability and long service life.

Product Drawing

How do I connect a pipe?(First)

Pipeline connection is a very important part of engineering construction, which is directly related to the quality of the project. With the rapid development of the pipeline industry, there are more and more ways to connect pipelines, but different pipelines have their own advantages and disadvantages, and also have different uses, and the correct selection of connection methods is very important.

1. Wire connection is connected by internal and external threads, pipes and pipes, pipes and valves. This connection is mainly used for the connection of steel pipes, copper pipes and high-pressure pipes. Advantages: simple manufacturing and use, reliable connection, easy to use, good versatility, can be assembled and reused, etc. Disadvantages: low pressure, easy to rot and leak at the thread. Thread assembly skills: after tightening, expose 2-3 tooth screw tails, remove excess filling, and paint red dan to prevent rust with exposed teeth. The coating width of Hongdan is consistent, the coating is uniform, and there is no flow and leakage.

2. Welding connection as the most traditional connection method, but also the most commonly used connection method in daily life, its main characteristics are the interface is firm and durable, the interface is highly sealed, no frequent maintenance, there are many commonly used welding methods. Advantages: the interface is firm and durable, not easy to leak, the joint strength and tightness are high, and there is no need for frequent management after use. Welding has the advantages of saving metal materials, high production efficiency and good joint sealing. Disadvantages: Welded joints are easy to produce large welding deformation and welding residual stress, thereby affecting the bearing capacity, processing accuracy and dimensional stability of the joint, and at the same time producing stress concentration at the junction of the weld and the pipe (heat affected zone), which has a great impact on the fatigue fracture of the joint. Welding defects (cracks, porosity, slag inclusion, not fused, not penetrated) are easy to occur in welded joints. The presence of these defects can reduce weld joint strength, cause stress concentration, and damage weld compactness.

3. Flange connection is to fix two pipes, pipe fittings or equipment on a flange plate first, and then add flange pads between the two flanges, and finally use bolts to tighten the two flanges to make them tightly combined. Advantages: flange connection has good strength and tightness, suitable for a wide range of sizes, can be applied in equipment and pipelines, so the application is the most common. Disadvantages: However, when the flange is connected, it cannot be assembled and disassembled quickly, and the manufacturing cost is high.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.