Malleable Iron 180R Reducing Cross BSPT Thread

Code:180R

Size: 3/4”*1/2”-4”*3”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 180R Reducing Cross. Reducing cross is a kind of connection pipe fittings commonly used in piping systems. It is used for changing the direction and diameter of the pipeline. Malleable iron reducing cross have four outlets and can connect two pipes with different diameters and different directions.The MI reducing cross is different from the standard MI cross. The standard malleable cross is made up of four intersecting circular tubes of the same diameter, and the four interfaces form a cross shape. As for the variable-diameter cross, there are two crosses with the same caliber and the other two with different calibers, that is, there are three crosses with different calibers. Therefore, when selecting and using reducing crosses, they need to be selected and installed according to the specific piping system needs.

DRAWING:

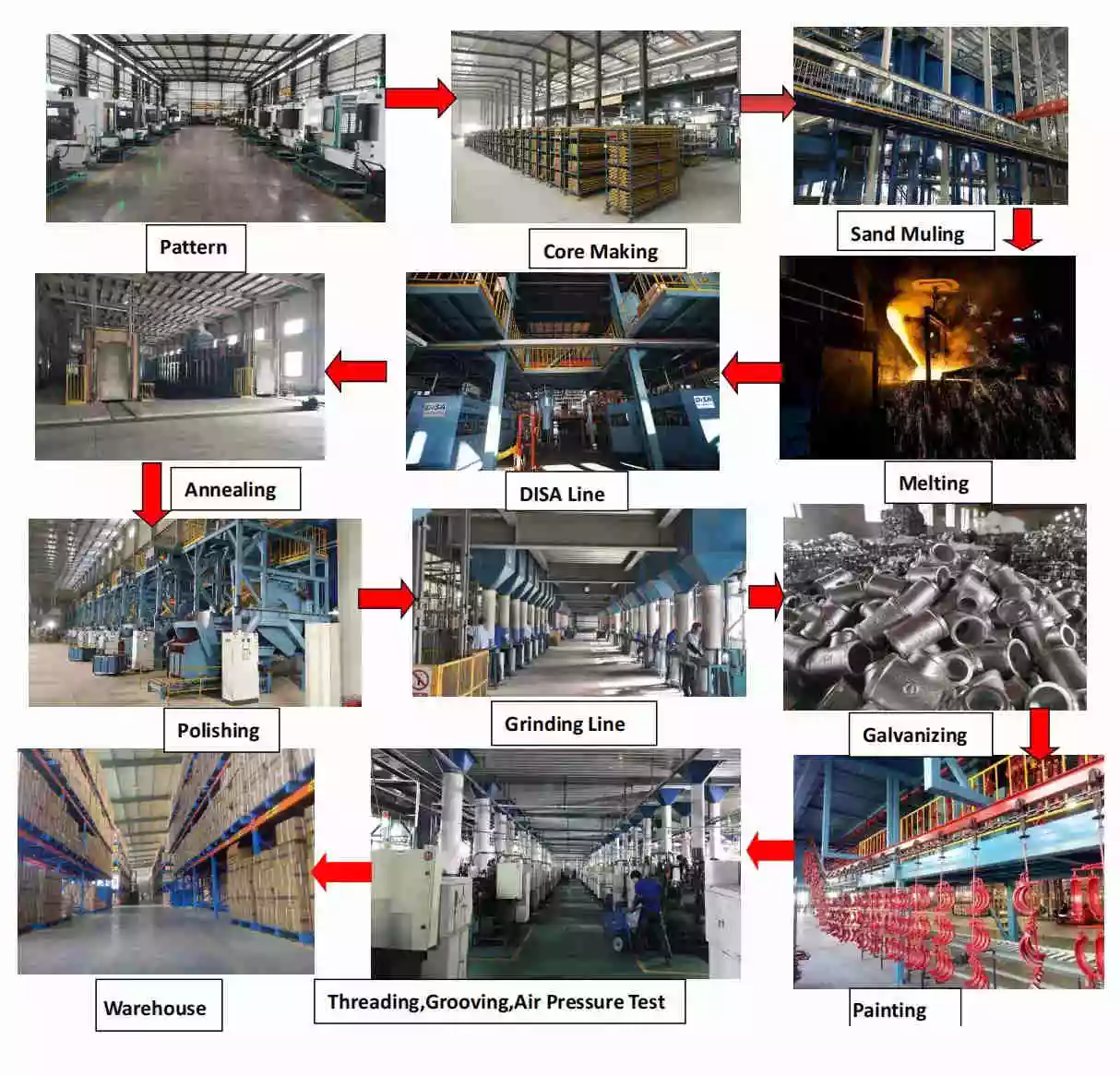

Production process:

The production process of Malleable Iron products is divided into modeling – smelting – pouring – annealing – polishing – correction – grinding – edging – galvanizing – threading, total 10 major processes.Every process is crucial and any problem in any process will cause the product to fail. We have inspectors in every process to check the malleable iron fittings one by one to ensure 100% qualified.

Our difference with others factory:

1. We have our own mold workshop and produce the molds ourselves to ensure the accuracy of the molds. And timely repair and improvement of molds to maintain the stability of product quality.

2. We have our own foundry to control product quality from the source.

3. We adopt the process of galvanizing first and then wire-coating. This is to avoid thread size deviations caused by the galvanized layer and ensure smooth installation. At the same time, it also avoids the problem of thread damage caused by product collision during the galvanizing process. This further ensures smooth installation when using the product.