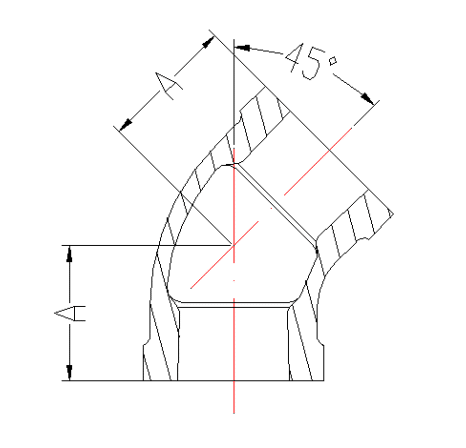

Malleable Iron 120 Elbow 45° NPT Thread

Code:120

Size: 1/4”-6”

Material: ANSI/ASTM A197-A,KTH350-10

Dimension: ANSI/ASTM B16.3/14/39

Thread: ANSI/ASTM B1.20.1,NPT

Pressure Rating: 363PSI,CLASS150

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

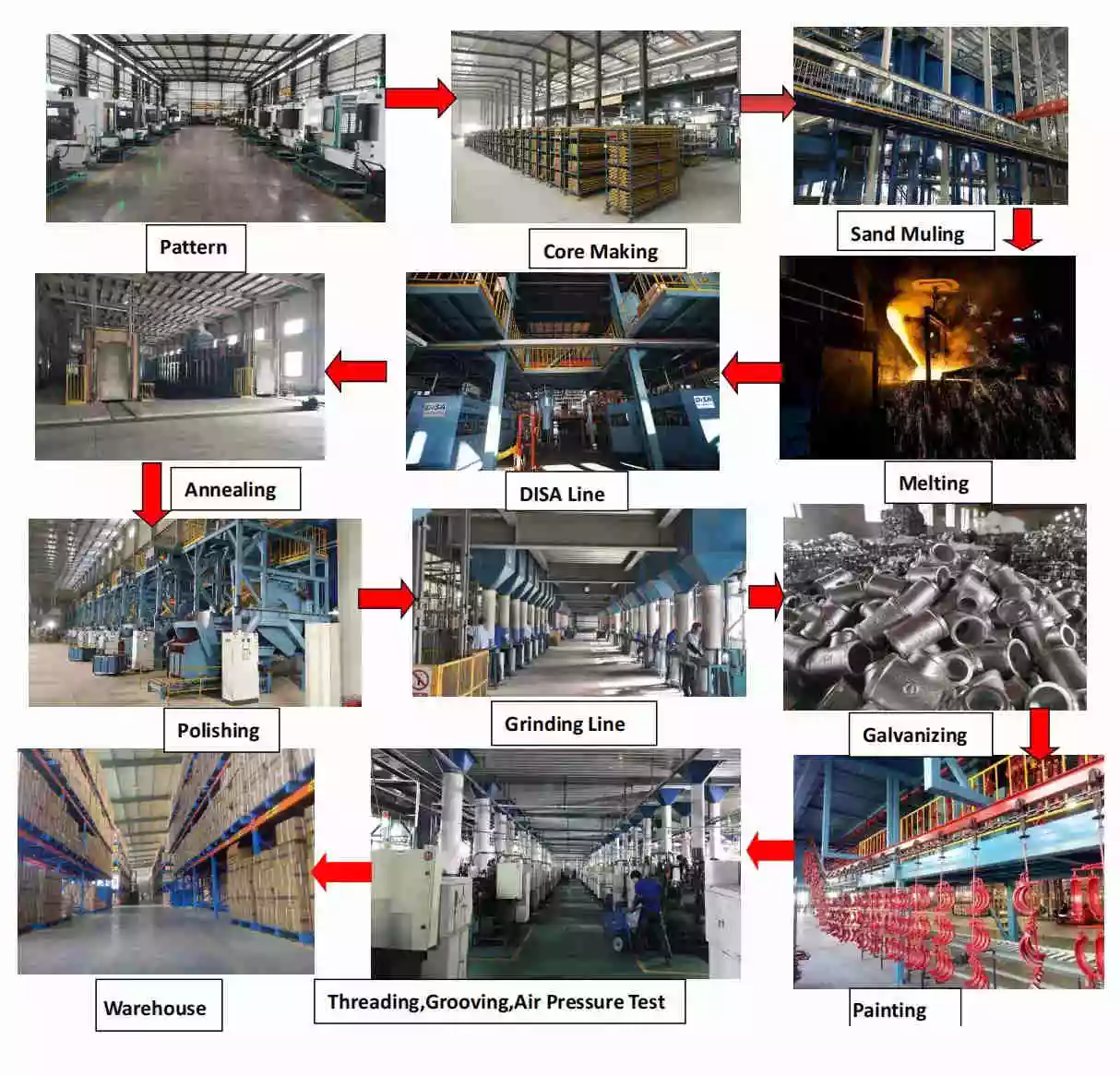

Product Description

Products Details

Malleable Iron 120 Elbow 45° . Malleable iron elbow 45° is a pipe fitting with a malleable iron pipe connection. It is a standard pipe fitting with a malleable iron pipe connection. It is used for connecting pipes in piping systems to change the direction or adjust the length of the pipeline. The main material of malleable iron elbow is malleable iron, which has good elasticity and strength.In the installation process, it should be noted that the use and installation of malleable iron elbow should comply with relevant national standards and installation specifications to ensure its safe and stable operation.

Product Drawing

The surface of malleable iron 120 Elbow 45°:

We have three methods for surface treatment of pipe fittings, namely black finish, electro-galvanized and hot-dip galvanized.

1.The black product,it is the original color of the BMI pipe fittings, which are coated with anti-rust oil to prevent rust. The BMI fitting is mostly used for fire-fighting system. After the customer installs it, it will be sprayed with fire-fighting red paint.

2.Electro-galvanized,namely cold galvanized.The malleable iron pipe fittings are passed through an electrolytic zinc solution, and zinc ions are attached to the surface of the pipe fittings under the action of electrodes to form a coating. Its advantages are uniform coating, smooth and beautiful surface, and low cost. The disadvantage is that the coating thickness is thin, and the coating on the inner surface is thin due to the isomagnetic effect of the electrode. The product can be used in oil and gas systems with low requirements for resistance to oxidation and corrosion.

3. Hot-dip galavanized. After the zinc ingot is dissolved by heating, a layer of zinc film is attached to the surface of the product through a hot dip process. Through the isolation of the zinc layer, the product is protected from oxidation and rust is prevented. Its advantages are thick coating, uniform and thick coating on the inner and outer walls, and long trial life.

Attention

We will recommend the most suitable malleable iron pipe fittings for customers based on their usage and budget. It not only meets the safety requirements of the project, but also minimizes the customer’s cost. Serve customers well with our most professional product knowledge