Malleable Iron 130R Reducing Tee NPT Thread

Code:130R

Size: 3/4”*1/2”-4”*3”

Material: ANSI/ASTM A197-A,KTH350-10

Dimension: ANSI/ASTM B16.3/14/39

Thread: ANSI/ASTM B1.20.1,NPT

Pressure Rating: 363PSI,CLASS150

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 130R Reducing Tee. Reducing tee is a component used for branch connection of pipelines. Reducing tee fittings are common in petrochemical plants and are generally used at the vertical intersections of branch pipes and main pipes. As a connecting component for pipeline branches, reducing tee fittings have high structural stress. During the service process, the stress situation of tee pipe fittings is much more complicated than that of straight pipes. It is one of the weak links in the pipeline system. Its quality has an important impact on the safe operation of the pipeline.

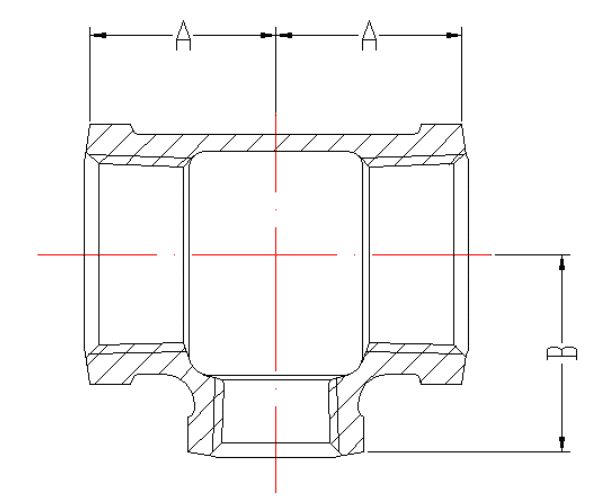

Product Drawing

Reducing tee fittings are available in the following types:

1. Classification according to pipe diameter: equal diameter reducing tee and variable diameter reducing tee.

2. Classification according to docking form: butt welding tee, socket tee, ferrule tee, threaded tee.

3. Classified by material: stainless steel tee, carbon steel tee, copper tee, PVC tee, ductile iron tee, malleable iron tee etc..

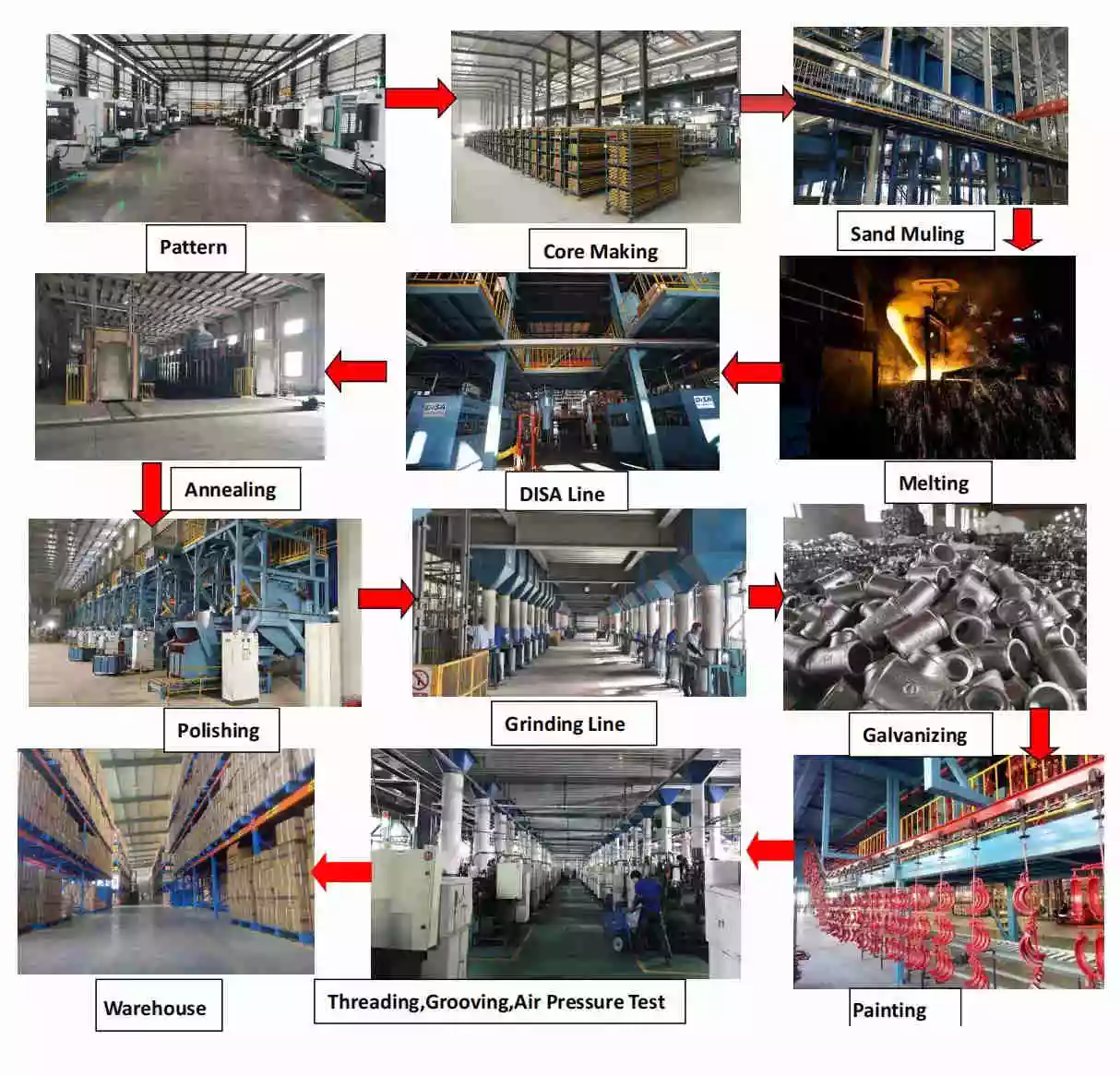

About the production of reducing tee

Reducing the stiffness of the malleable iron reducing tee can effectively reduce its structural stress and improve the safety and reliability of the pipeline system. Therefore, during the design and manufacturing process of reducing tee fittings, special attention should be paid to reducing their stiffness to ensure the normal operation and service life of the pipeline system.