Malleable Iron 240 Socket Reducing NPT Thread

Code:240

Size: 3/8‘’x1/4”-6”x4‘’

Material: ASTM A197/A197M

Dimension: ASME B16.3, B16.14

Union Dimension:B16.39

Thread: ASME B1.20.1

Pressure Rating: 363PSI,CLASS150

Surface Treatment: Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

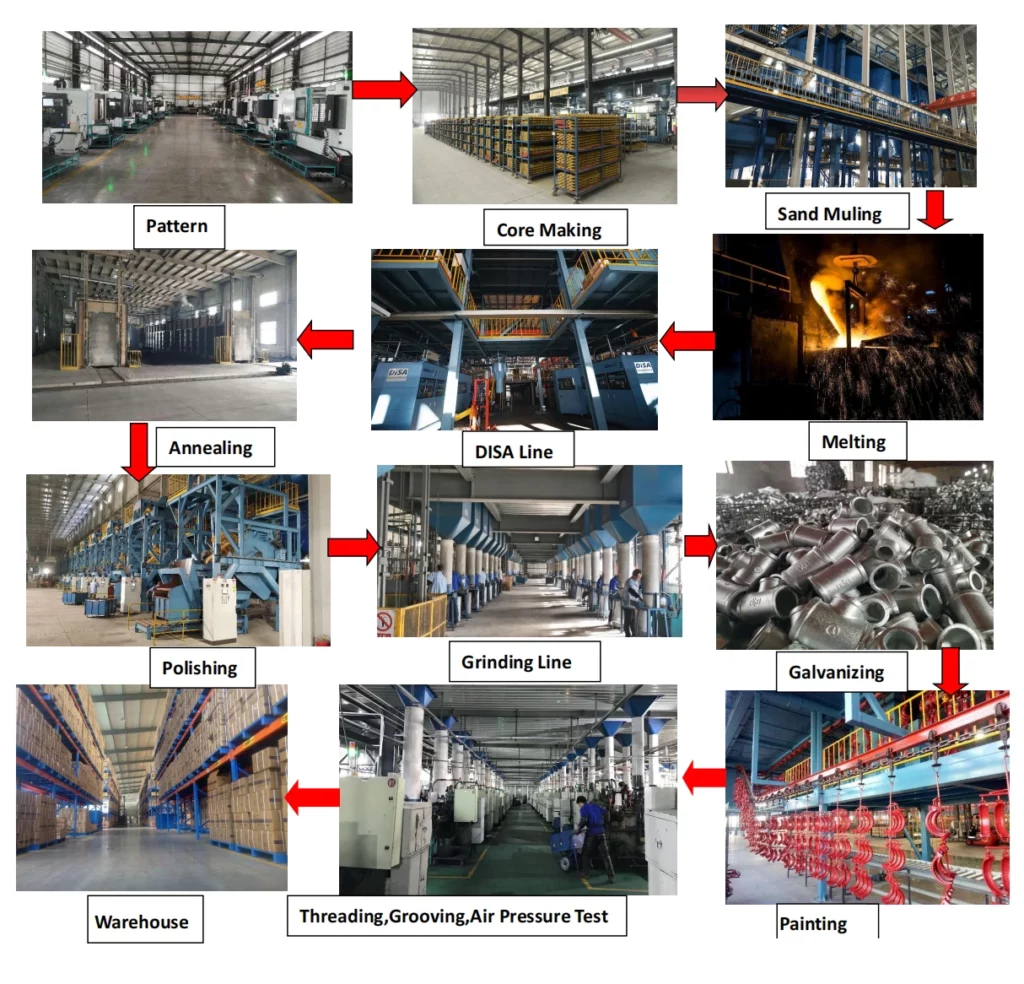

Product Description

Products Details

Pipe socket-coupling, it is a commonly used accessory in industrial pipe connection. A short section of pipe used to connect two tubes. Also called external connector. The materials are: carbon steel, stainless steel, alloy steel, etc. The connection methods are: threaded connection, welding. First: according to its manufacturing process, it can be divided into two types: forging and casting. Forging refers to the formation of steel ingots or round bars after heating forging and forming, and after processing threads on a lathe, casting refers to the melting of steel ingots and pouring into a fixed pipe hoop model, waiting for it to cool down. Second: according to the type of connection, it can be divided into two types: thread and socket welding. Third: The main manufacturing standards of pipe hoops are generally GB/T14383, ASME B16.11, BS 3799

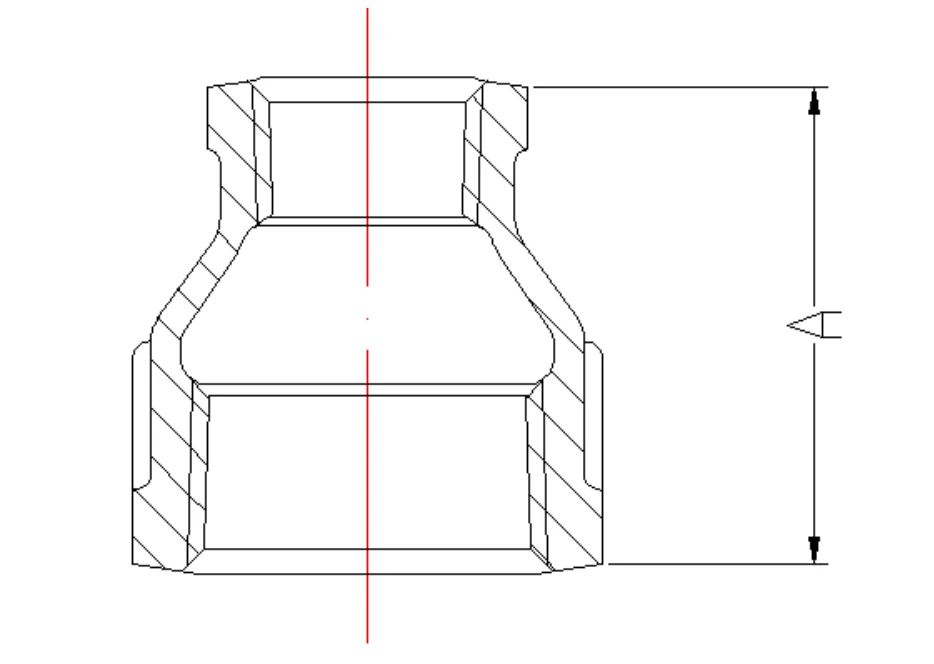

Product Drawing

How to distinguish the types of threads? (Chapter 1)

BSPT and BSP British specification taper thread, NPT American specification taper thread, PT Japan old JIS specification taper thread, equivalent to ISO specification R, Rc, DIN2999 European mainly German pipe thread

1.NPT

NPT is the American standard tapered pipe thread for general use. where N represents the National (American) American National Standard, P represents the PIPE tube, T represents the TAPER cone, and the tooth angle is 60°. This pipe thread is commonly used in North America or is often seen in the use of ANSI specifications. The national standard can be found in GB/T12716-1991. It is important to note that NPT teeth must be used in ANSI specifications.

2.PT

PT teeth are imperial tapered threads with a tooth angle of 55°, which is most commonly used in seals. Mostly used in Europe and Commonwealth countries, in fact, in Taiwan, Japan JIS specifications also follow imperial norms, and China actually uses imperial screws. It belongs to the Wyeth thread family. The national standard can be found in GB/T7306-2000. Inch pipe threads are fine threads, because the depth of the teeth of the coarse thread will seriously reduce the strength of the cut thread outer diameter pipe. In addition, in the actual small pipe diameter pipeline, NIPPLE is often used, the purpose is that the purchased NIPPLE wall thickness is relatively thick, can ensure the strength of the tapping part, and the main line does not need a thick pipe wall, so as to save costs. PF teeth are tubes with parallel threads. It must be noted that PT teeth must be used in the JIS specification, etc.

3.G thread

G is a 55 degree non-threaded sealed pipe thread and belongs to the Wyeth thread family. Labeled G stands for cylindrical thread. The national standard can be found in GB/T7307-2001. G is the general term for pipe threads (Guan), and the division of 55 and 60 degrees belongs to the functional, commonly known as the pipe circle. That is, the thread is machined from a cylindrical surface.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.