Malleable Iron 310 Backnut BSPT Thread

Code:310

Size: 1/2”-4”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 310 Backnut. Malleable iron Backnut is a common metal product made of cast iron, also known as malleable nut or hexagonal nut. Its main characteristics are high strength, good toughness, strong tensile strength, can withstand large impact forces, and is not easy to break. In addition, Malleable iron backnut also has good corrosion resistance and can be used in a variety of environments for a long time.

DRAWING:

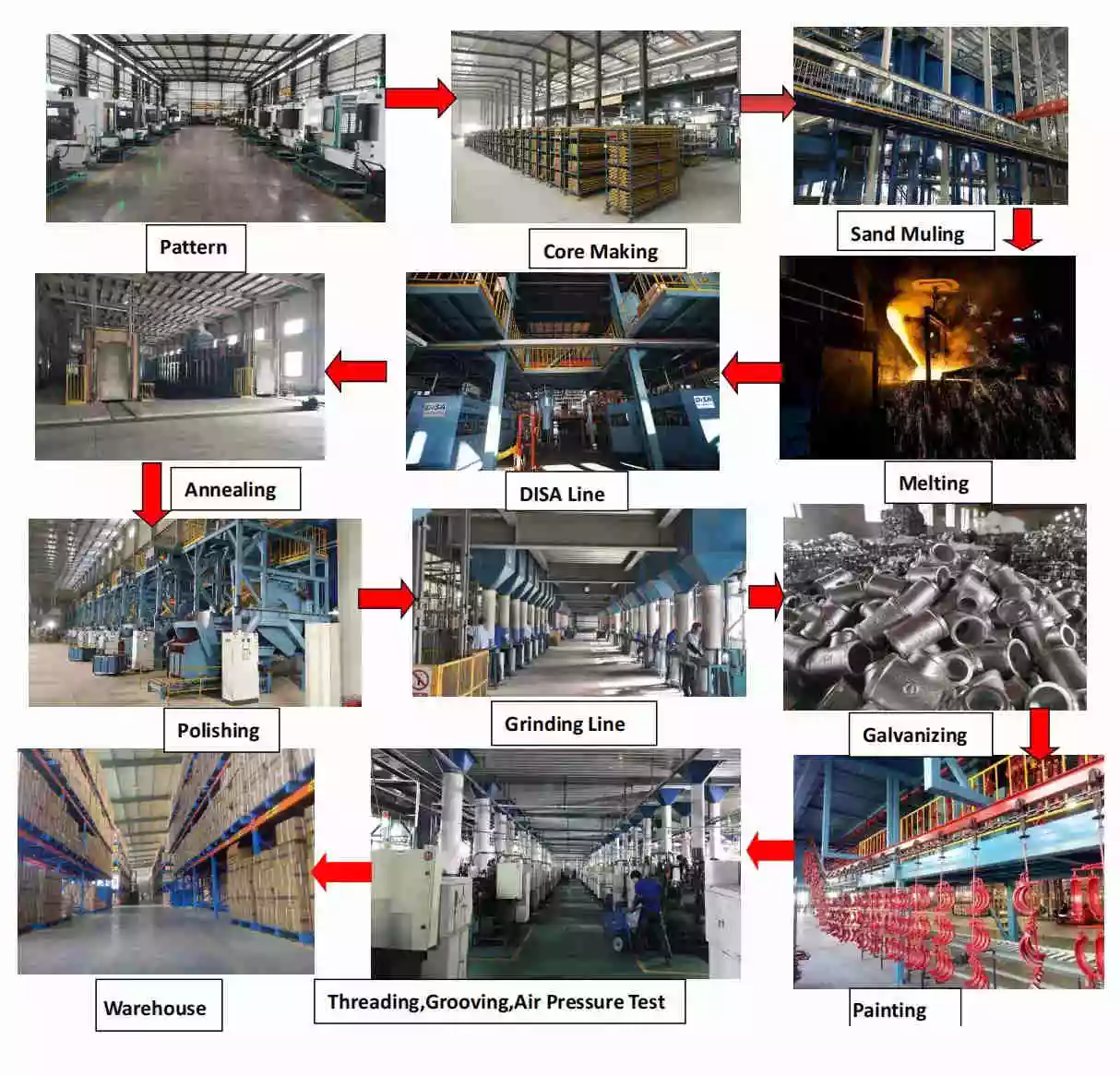

The process:

4-Annealing

Annealing is a metal heat treatment process, which refers to slowly heating the metal to a certain temperature, maintaining it for a sufficient time, and then cooling it at an appropriate speed. Graphitization annealing refers to the decomposition of cementite Fe3C and the elimination of the presence of flake graphite structure (gray iron) during the annealing process. A matrix of ferrite + flocculent graphite is formed. If the annealing process is immature, there will be residual gray iron (flake graphite structure) in the core, and the cross section will be gray, which is what we call gray parts.

What is Annealing?

The existence of supercooling during the pouring and solidification process will produce differences in grain growth sizes. Annealing can refine the grains and improve the mechanical properties of castings.

Due to the volume change caused by the allotropy phenomenon during the solidification process of the molten metal, internal stress will be generated. The annealing process can eliminate the residual internal stress, stabilize the size, and reduce the tendency of deformation and cracks.

The annealing process of Malleable Steel pipe fittings is carried out to achieve the above purposes.