Malleable Iron SCC Short Compression Coupling BSPT Thread

Code:SCC

Size: 1/2”-2”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

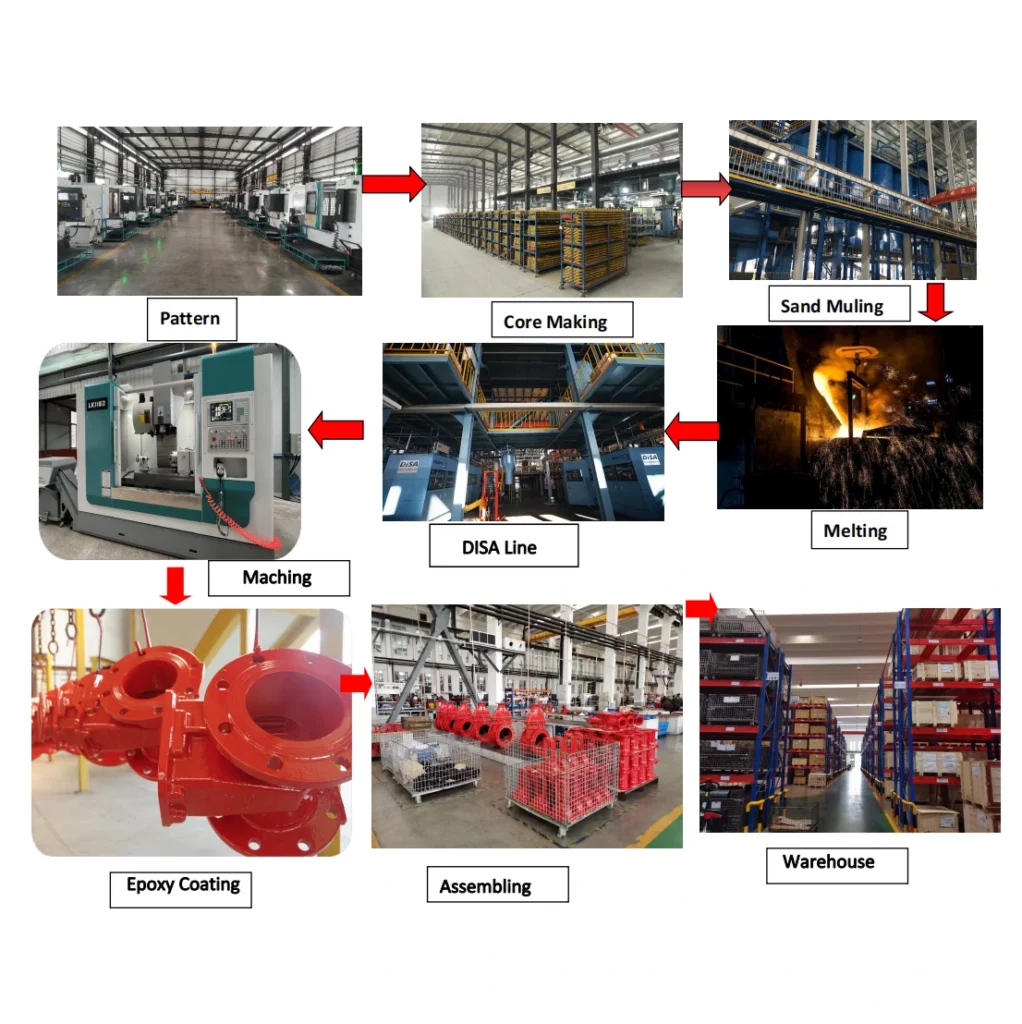

Malleable Iron SCC Short Compression Coupling. SCC is a kind of connection pipe fittings commonly used in plumbing installation,Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems. It is used for the connection of pipe bends. According to the production process, it can be divided into: welding elbow, forged elbow, push elbow, casting elbow, butt welding elbow, etc. Malleable Iron SCC Short Compression Coupling is a kind of casting coupling, through melting, annealing, and then machined into pipe fittings. This material pipe fittings have good malleable castability, are relatively easy to process, and have a certain strength. Fittings are used in piping systems with working pressures between 1.6MPa to 2.5MPa. The connection of the piping system is connected by threads, and the threaded connections are sealed with pipe thread seal tape or sealant. There are three ways of surface treatment of pipe fittings: hot-dip galvanizing, electro-galvanizing and black. Galvanizing can make the pipe fittings have good anti-rust, anti-corrosion and other properties. Hot-dip galvanizing is done by placing the pipe filigents in the melted zinc liquid, and the thickness of the zinc layer is relatively thick, which can reach more than 70um. Electro galvanizing, also known as cold galvanizing, is to put the zinc block in the electrolyte, and then through electrostatic adsorption to make zinc ions attach to the surface of the pipe fittings, the thickness of the zinc layer is uniform, but the thickness of the zinc layer is thin, the thickness is more than 25um.

Product Drawing

Quality Control:

“Chain-and-cable quality management” is a system of layer-by-layer mutual inspection in the production process, one link after another, the whole process has no omissions, timely detection of defective pipe fittings and product defects, through layer-by-layer mutual inspection, every worker become inspectors of the previous process, and at the same time link the inspection work with the performance income of the workers, stimulate the enthusiasm of the workers, actively and quickly find defective pipe fittings or defective malleable iron pipe fittings, and correct them in time, which not only ensures the qualified rate of the GI fittings, but also reduces the risk due to Production costs caused by defective MI fittings.

The quality of the pipe fittings can pass the examination and certification of most countries in the world. At present, the international certifications we have obtained are as follows:

United States: FM, UL certification

EU: CE certification

Brazil: ABNT certification

Turkey: TSE certification

Indonesia: SNI certification

Our advantage -3

The most beautiful appearance

Due to years of experience in molding and casting and leading technical advantages, the smoothness of the appearance of Fluid Tech pipe fitting is the best in China, and the galvanized surface is smooth and flat. Due to the fine sand, there are no large sunken sand hole residue marks on the surface of malleable iron pipe fittings. At the same time, in order to avoid the flash left by the mold clamping mark, Fluid Tech uniquely designed the mold clamping seam as a reinforcing rib in the mold design, which not only improves the appearance of the mold, but also strengthens the stability of the casting at the mold clamping position , improve stress resistance. Put an end to the defect of zigzag flash left by other manufacturers at the mold joint.