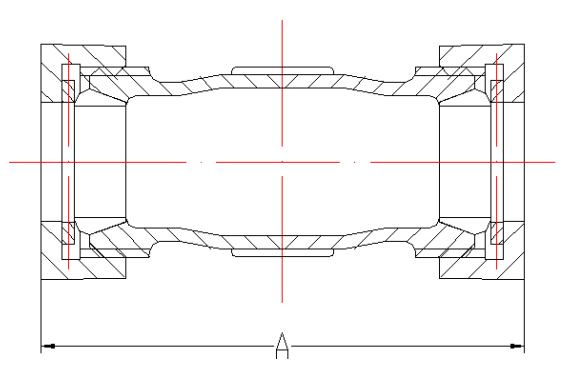

Malleable Iron LCC Long Compression Coupling BSPT Thread

Code:LCC

Size: 1/2”-2”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron LCC Long Compression Coupling. LCC is a kind of connection pipe fittings commonly used in plumbing installation,Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems. It is used for the connection of pipe bends. According to the production process, it can be divided into: welding elbow, forged elbow, push elbow, casting elbow, butt welding elbow, etc. Malleable Iron LCC Long Compression Coupling is a kind of casting coupling, through melting, annealing, and then machined into pipe fittings. This material pipe fittings have good malleable castability, are relatively easy to process, and have a certain strength. Fittings are used in piping systems with working pressures between 1.6MPa to 2.5MPa. The connection of the piping system is connected by threads, and the threaded connections are sealed with pipe thread seal tape or sealant. There are three ways of surface treatment of pipe fittings: hot-dip galvanizing, electro-galvanizing and black. Galvanizing can make the pipe fittings have good anti-rust, anti-corrosion and other properties. Hot-dip galvanizing is done by placing the pipe filigents in the melted zinc liquid, and the thickness of the zinc layer is relatively thick, which can reach more than 70um. Electro galvanizing, also known as cold galvanizing, is to put the zinc block in the electrolyte, and then through electrostatic adsorption to make zinc ions attach to the surface of the pipe fittings, the thickness of the zinc layer is uniform, but the thickness of the zinc layer is thin, the thickness is more than 25um.

Product Drawing

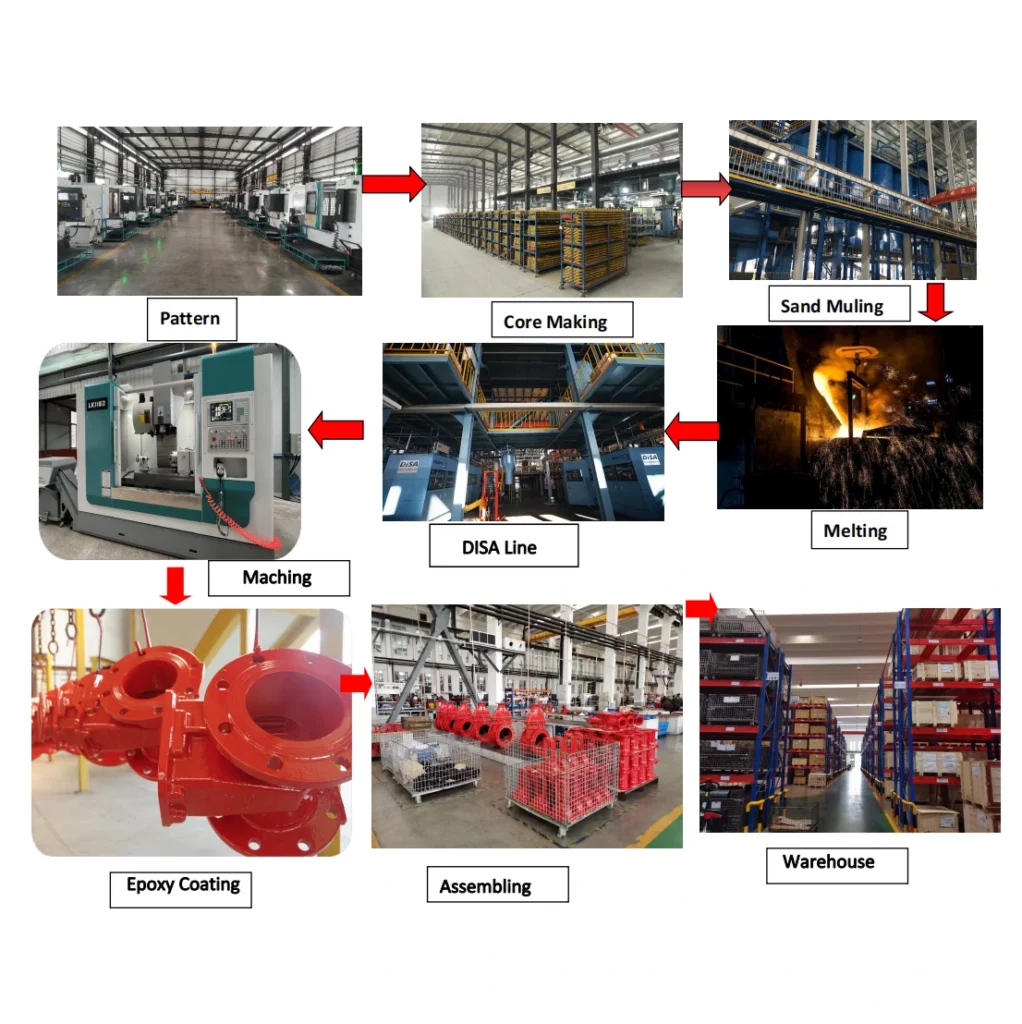

Quality Control:

Fluid Tech invented the “chain-type quality management” and won the “First Prize for Enterprise Management Modernization Innovation Achievements” from the Ministry of Agriculture. The quality of malleable iron pipe fittings must be strictly controlled in every process. During the operation of the next process, the quality of the MI fittings transferred from the previous process will be strictly and carefully inspected. If any BMI fittings found to be unqualified in the previous process must be eliminated. Those found to be unqualified in the previous process will be rewarded, and those found to be unqualified in the next process will be punished.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.

Our advantage

Quality First

We are a pipe fittings supplier for the entire fluid system and we have our own factory to produce the best quality pipe fittings. For customers’ needs for other pipe fittings which we don’t produce, we will select the best quality fittings on the market to supply to customers. We firmly believe that quality of the fitting is the first factor. Although the malleable iron pipe fittings is not expensive, its role in the entire system is crucial, and the losses caused by inferior fittings are expensive. So quality first is our standard