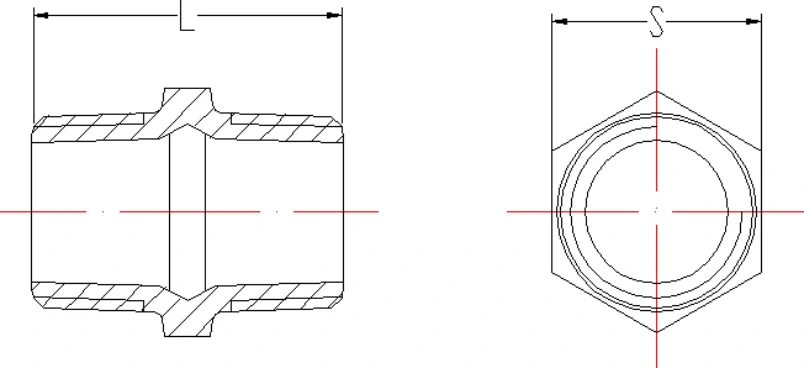

Malleable Iron 280 Hexagon Nipple NPT Thread

Code:280

Size: 1/4”-4”

aterial: ASTM A197/A197M

Dimension: ASME B16.3, B16.14

Union Dimension:B16.39

Thread: ASME B1.20.1

Pressure Rating: 363PSI,CLASS150

Surface Treatment: Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

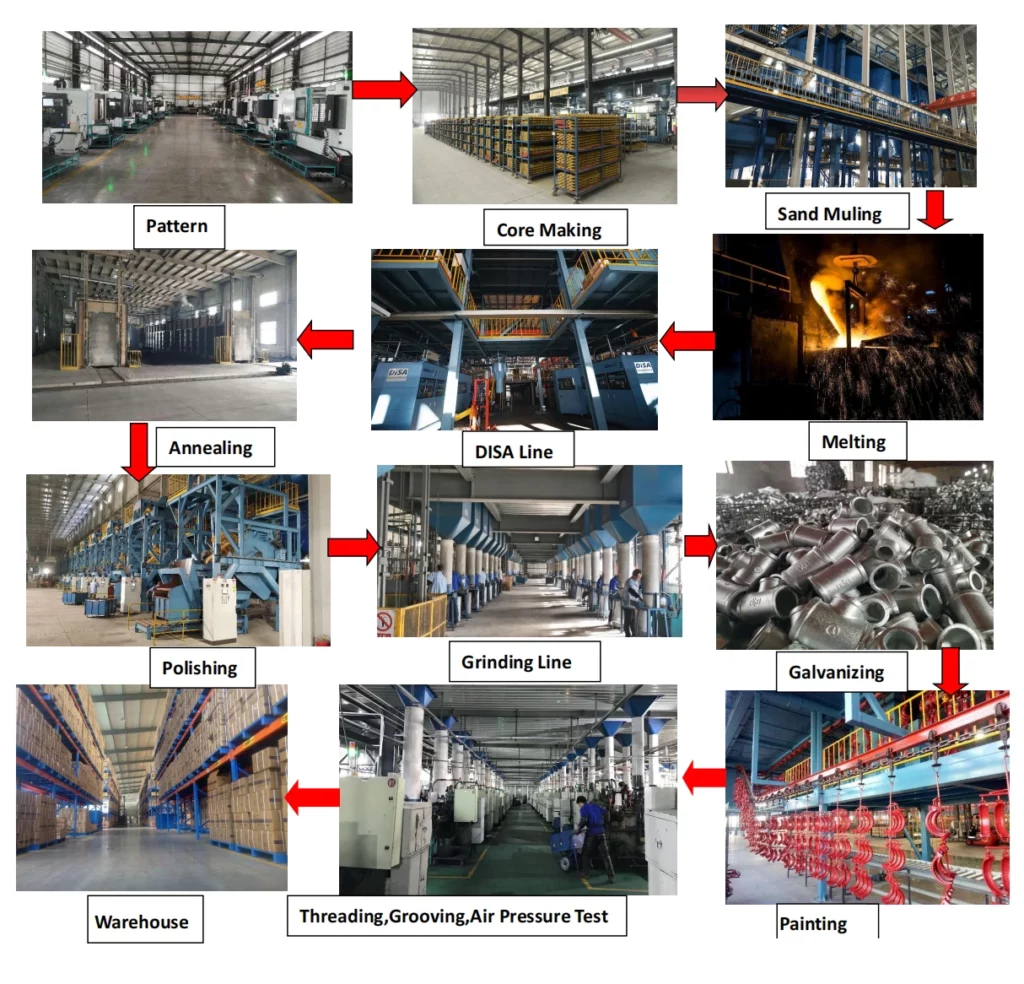

Product Description

Products Details

The NPT threaded hex nipples fitting size is an accessory that consists of a short tube. The pipe usually has a male thread at each end to connect the other two fittings. A Hex thread nipple firings ASME B16.3, B16.14, ASME B16.11 is for forged thread hex nipple fittings for internal thread fittings. NPT pipe fittings and other pipes. ASME B16.3, B16.14 cast iorn threaded hex fittings range in size from 1/4″ to 4″. These threaded hex fitting tubes can be manufactured and polished to customer specifications.

Product Drawing

How do I connect a pipe? (Second)

4. Groove connection is in the pipe joint and other parts of the processing to form a ring groove, with clamp parts, rubber sealing ring and fasteners composed of sleeve type quick connector, installation, after the adjacent pipe end sleeve special-shaped rubber sealing ring, with a split clamp connection, the inner edge of the clamp part is located in the groove and fastened with fasteners, to ensure the sealing performance of the pipeline. This connection method has the advantages of not damaging the galvanized layer of the steel pipe, fast construction, good sealing and easy disassembly. It can be used for building water supply, fire water supply, production water supply and other pipeline projects. Advantages: simple operation, the original characteristics of the pipeline are not affected, conducive to construction safety, good system stability, convenient maintenance, good economic benefits.

5. Ferrule connection (aluminum-plastic composite pipe): the connection method of pressing the pipe on the pipe fittings with a lock nut and an open pressing ring. Features: Tube pipe fittings short sealing surface, easy and simple installation, no special tools, can be disassembled, generally used in tap water and gas systems below 2632 specifications. Advantages: reliable connection, high pressure resistance, temperature resistance, good sealing and repeatability, convenient installation and maintenance, safe and reliable work, etc.

6. In chemical pipelines, cast iron pipes used for water transmission mostly use socket connections. Socket connection is suitable for cast iron pipe, ceramic pipe, plastic pipe, etc. It is mainly used in the upper and lower water pipelines with low pressure. Cyan lead interface is the earliest interface form used in socket cast iron pipe, which has good elasticity, rigidity and seismic resistance, and does not require maintenance after construction. However, lead is a relatively valuable metal, and the cost of a large amount of consumption engineering is too high. It is mainly used in places with large vibrations, such as crossing railways, highways, riverbeds and emergency repairs.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.