Mech Tee Grooved Outlet

Code:XGQT03

Size: 6”-10”(DN150-DN250)

Material: Ductile iron ASTM A536, 65-45-12

Dimension: ISO6182、AWWA C606、GB 5135.11

Connection:ASME B36.10、ASTM A53-A53M、ISO 4200

Thread: If have ISO 7-1,BS 21,BSPT, NPT,ASME B1.20.1

Pressure Rating: 175PSI-500PSI

Surface Treatment: Red Painting,Epoxy Coating ,Hot-Dip Galvanized,Electroplated

Bolt & nut: ASTM A449/ CLASS 8.8/ ISO 898

Gasket: EPDM, Nitrile, Silicone rubber, etc.

Certificate: UL Listed / FM Approved

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

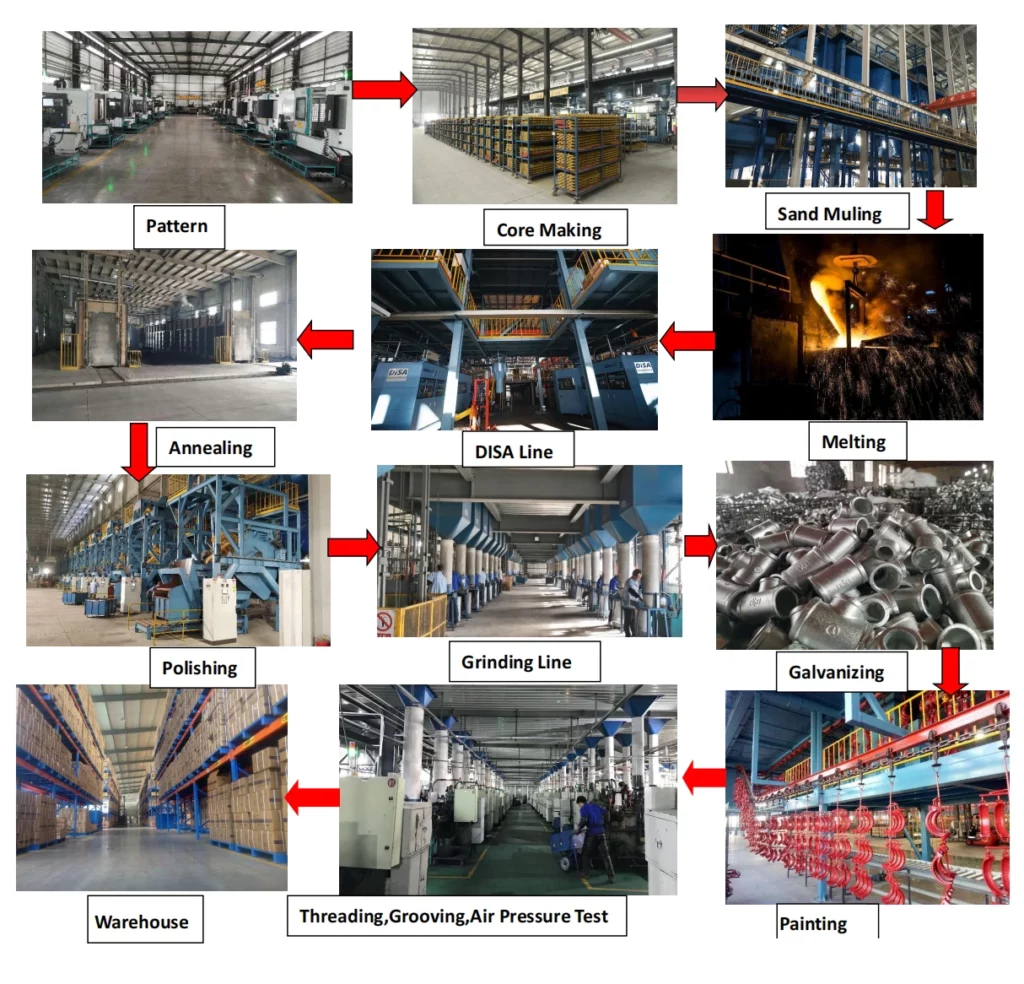

Product Description

Products Details

Ductile iron mechanical tee Grooved end ,Mechanical tee Grooved end ,Mech Tee ,Mechanical Tee thread end. Mech Tee thread end.Tee is also known as pipe fittings tee or tee fittings, tee joints, etc. It is mainly used to change the direction of the fluid, and is used in the main pipeline to branch the pipe. Mechanical tees are divided into grooved mechanical tees and threaded mechanical tees. It can be used to directly connect branch pipes on steel pipes, and has more applications in the installation of fire pipes and sprinkler pipes. When shunting or merging is required, a mechanical tee can be used to first open a hole in the steel pipe with a hole opener, and then the mechanical tee is snapped into the hole, and the hole is sealed along the pipe wall by a sealing ring around it.

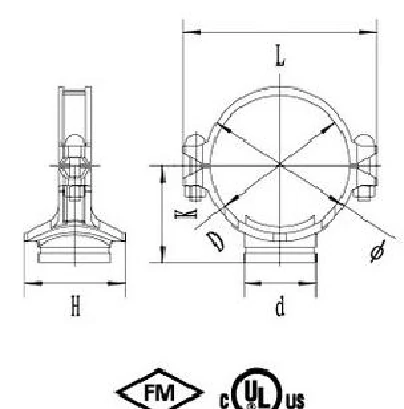

Product Drawing

Mechanical tees with grooved branches provide additional trench outlets in existing pipes by connecting preset holes in the surface of the main pipe. Mechanical tee details

When splitting or merging is required, mechanical tees can be used. First, use a tapping machine to make a hole in the steel pipe, and then snap the mechanical tee into the hole, and the perimeter of the hole is sealed with a sealing ring along the pipe wall. When the mechanical tee is connected, the gap between the mechanical tee and the hole should be checked, all parts should be uniform, and then tightened in place; The distance between mechanical tee openings should not be less than 1m.

Mechanical tees help you retrofit and extend sprinkler systems. A tee is a fitting with three outlets, two on a line with a 90-degree exit between the third. In a sprinkler system, the heavier main water pipe transports water into the building, and the lighter branch distributes it to the sprinkler. Tees connect the feeders to the main line and take into account various variations in elevation and the direction of pipes and water.

Please click, If you consider more detailed information