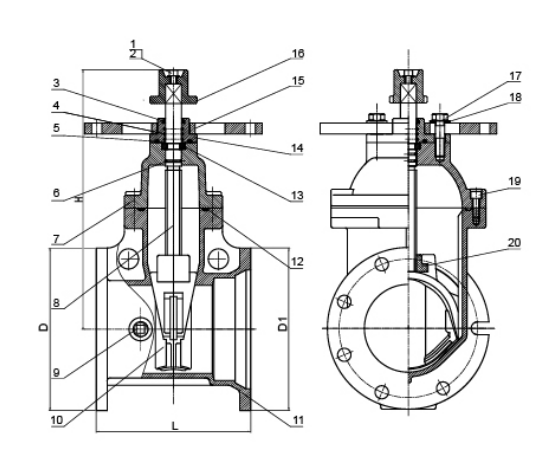

Flanged x Mechanical Joint End Resilient Wedge NRS Gate Valve Z45-300FJA

Code:Z45-300FJA

Size: 2″-12”(DN50-DN300)

Material: Ductile iron ASTM A536, 65-45-12/Cast Iron ASTM A126 Class B/EN-GJS-450-10/ ENJS1040

Dimension: AWWA C515,ASME B16.10,BS5163,AWWA C503, BS & DIN Standard, BS750,EN1074,BS EN14339, BS 5041, BS 5154

Connection: AWWA C606, ASME B16.1 CL 125, ISO 5211,ASTM A888, ISO 6182, BS EN 1092-2

Pressure Rating: 300PSI

Temperature: -10-120 ℃

Surface Treatment: ANSI/AWWA C550,Epoxy coated interior and exterior by Electrostatic

Certificate: UL Listed/FM Approved /NSF/ANSI61&NSF/ANSI 372

Medium: Water, gas etc.

We’re here to help:

Easy ways to get the answers you need.

Product Description

PRODUCTS DETAILS:

Product Drawing

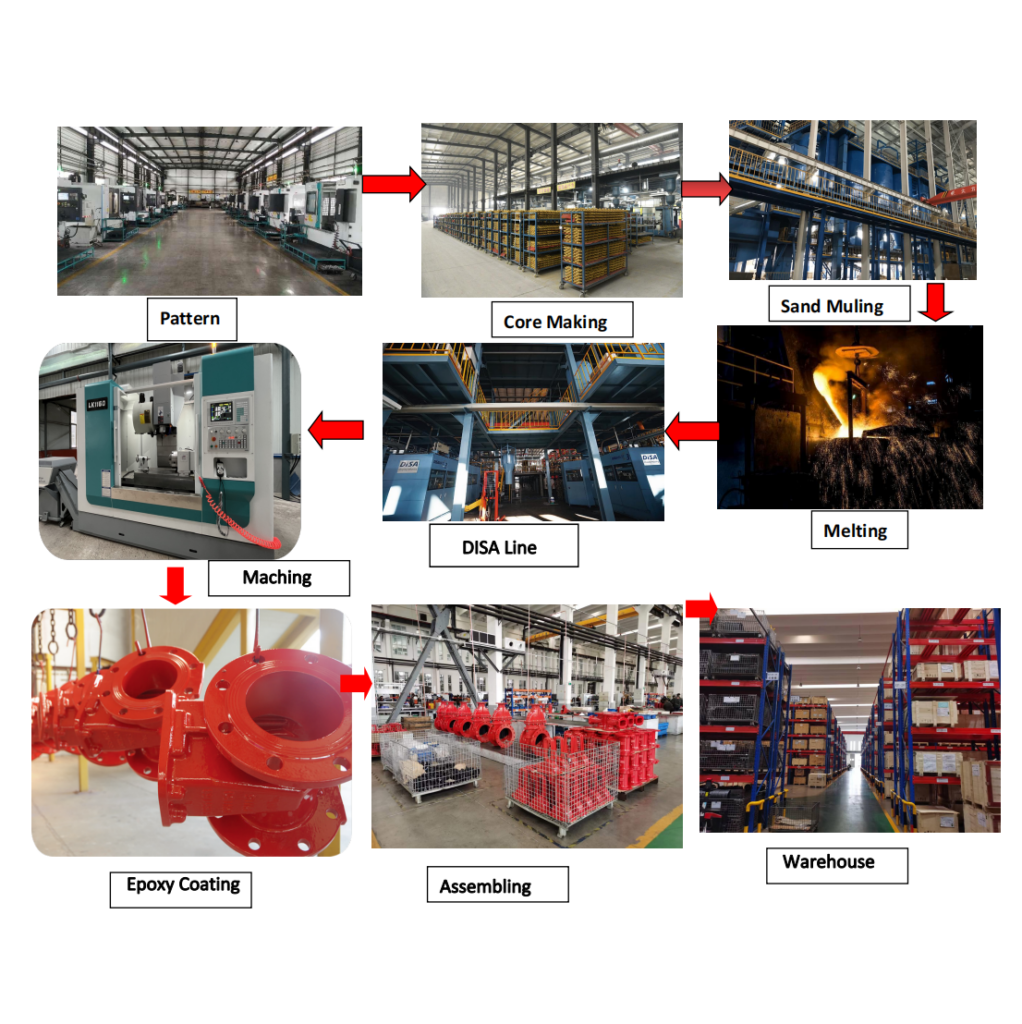

Quality Control

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as China Taiwanese Building 101, Xiamen Building,Wuhan Expo Building and other famous landmark projects.