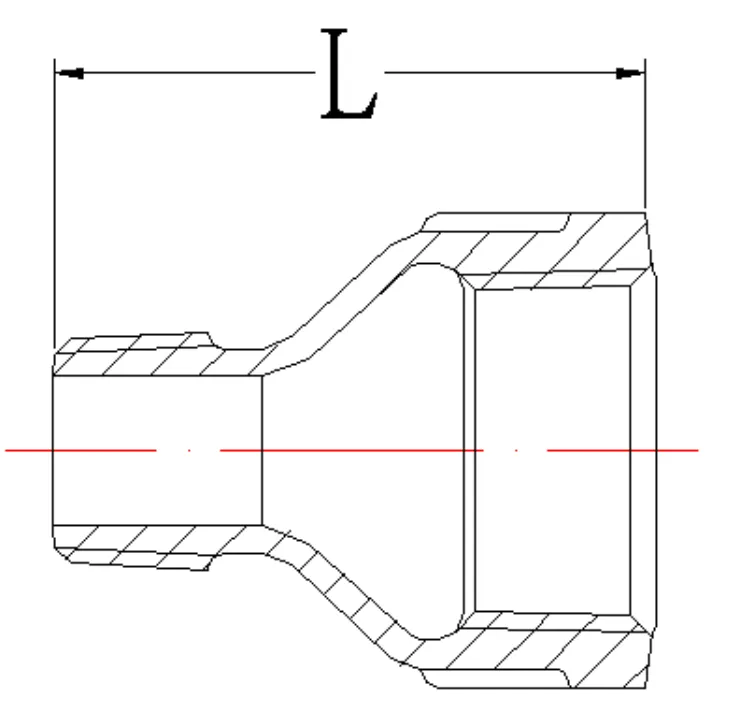

Malleable Iron 246 Reducing Socket M/F NPT Thread

Code:246

Size: 3/4”*1/2”-2”*1-1/2”

Material: ANSI/ASTM A197-A,KTH350-10

Dimension: ANSI/ASTM B16.3/14/39

Thread: ANSI/ASTM B1.20.1,NPT

Pressure Rating: 363PSI,CLASS150

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

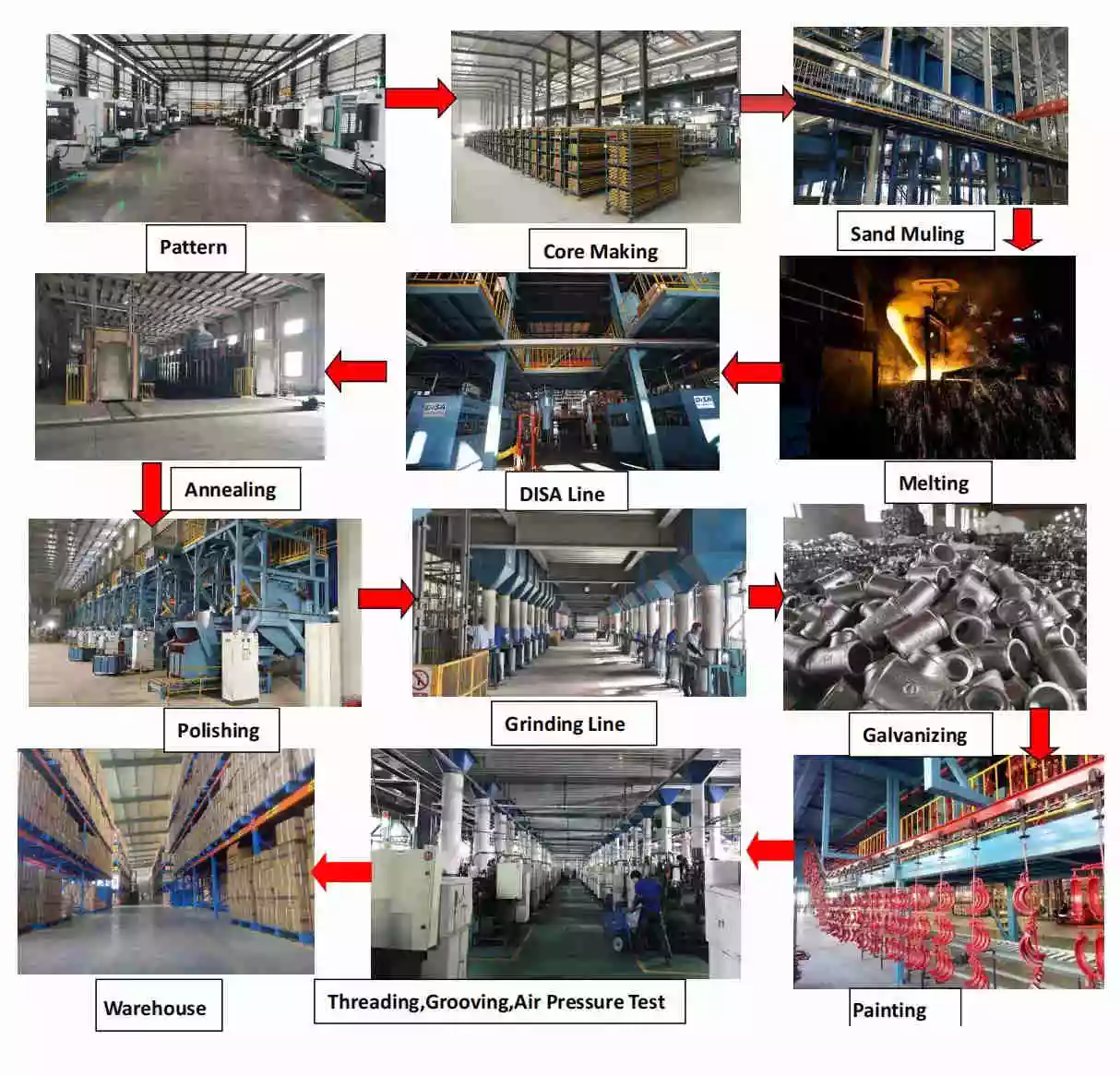

Product Description

Products Details

Malleable Iron 246 Reducing Socket M/F. Reducing Socket M/F is a kind of socket to connect the pipes or fittings with different diameter. The surface of reducing socket can be hot-dip galvanized, electrical galanized or black. The fittings will be with anti-rust oil.

Product Drawing

American standard Thread

The standard is ANSI/ASTM B1.20.1 and include tapered and parallel teeth for a variety of uses including rigid, pressure sealing or both. The thread angle (the angle between the thread side and the vertical plane of the bolt axis) is 60 degrees. The peak/trough of the spiral (the most protruding top of the thread is called the spiral peak, and the most concave point of the thread is called the spiral valley) presents an acute angle. There are abbreviations for various subdivision types due to their uses. The common NPT is the abbreviation of American tapered teeth, and the American parallel teeth are abbreviated as NPS. Mainly used in North America.

What is NPT or NPS

NPT: National pipe thread, full name: American National Standard Taper Pipe Thread. It is an American tapered thread standard commonly used in general industrial components. It is often used for sealing industrial components that cannot or do not require any seals, and have a wide range of applications. It can be used in external threaded and internal threaded.

NPS: National pipe straight, full name: American National Standard Straight Pipe Thread. It is an American parallel thread standard commonly used in general industrial components. For rigidity requirements, seals need to be used; It can only be internal threaded.