Malleable Iron 270 Parallel Thread Socket BSPT Thread

Code:270

Size: 1/4”-6”

Material: BS EN 1562,EN-GJMB-350-10,KTH350-10

Dimension: BS EN 10242

Thread: ISO 7-1,BS 21,BSPT

Pressure Rating: PN16/PN25

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 270 Parallel Thread Socket. Parallel Thread Socket is a kind of connection pipe fittings. The inner is entire threaded with BSPT, also named entire thread coupling. The another socket is part thread Socket, the inner middle of the socket is without thread also called part thread coupling. Both of them are FM approved and UL listed and the function of these two kinds of socket is the same, but different countries have different usage habits. We will recommend the most suitable products to customers based on local usage habits.

DRAWING:

What is malleable iron pipe fitting:

Malleable iron pipe fittings are casting iron fittings. Casting is a molding method that smelts metal, makes a mold, pours the molten metal into the mold, and then cools and solidifies to obtain a casting with a certain shape and performance. There are many methods of casting, which are often divided into two categories: sand casting and special casting. Fluid tech’s Malleable iron pipe fittings are produced using sand casting methods.

Sand casting refers to designing and making molds and core boxes according to the shape and size of the pipe fittings, preparing the molding sand and core sand, using the mold and molding sand to shape, using the core box and core sand to make the core, and then combining the boxes to obtain the casting mold. The metal is poured into the mold, cools and solidifies, and the casting is obtained.

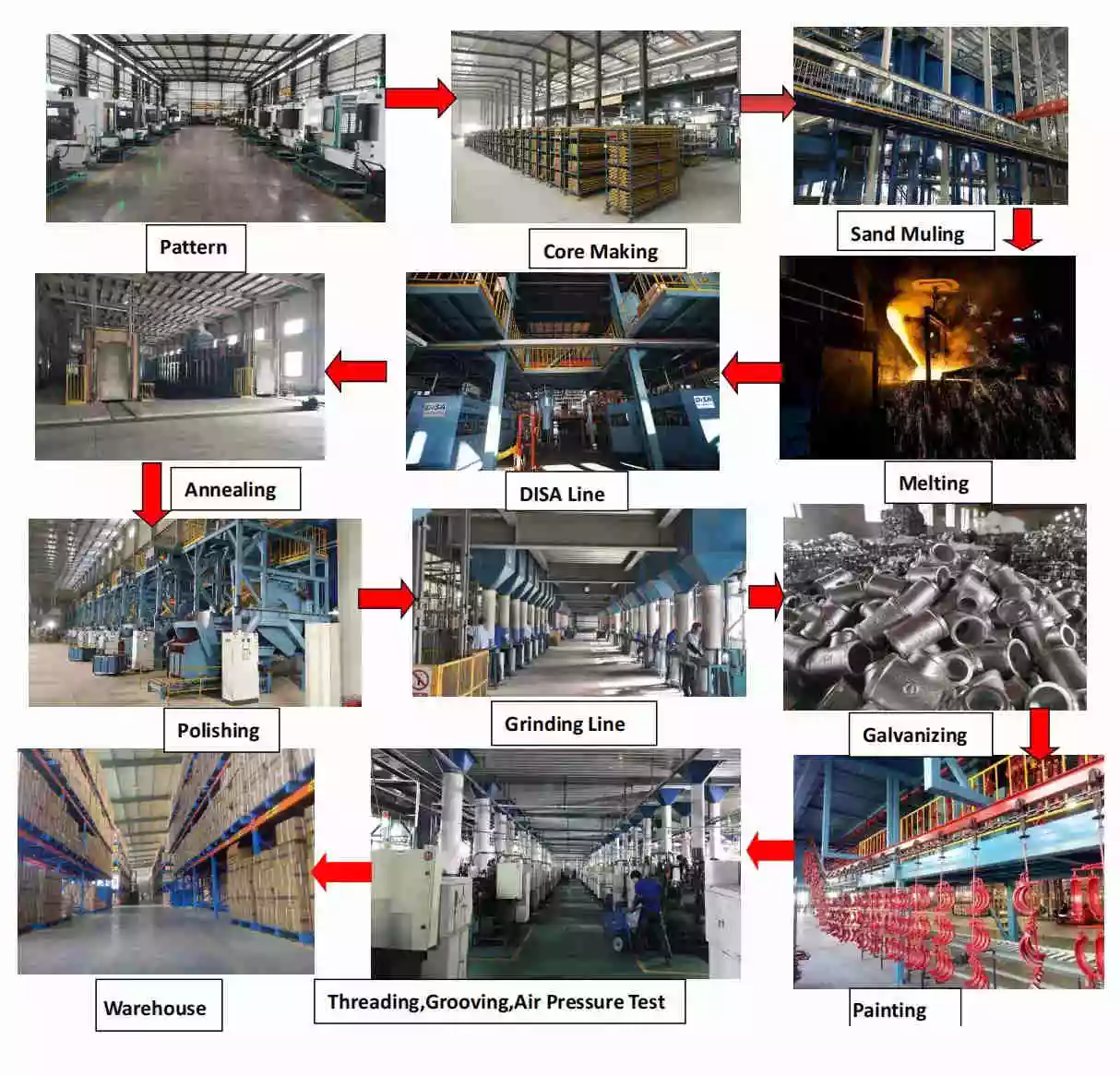

Production process

1. Molding

Molding refers to the process of making molds in the casting process.

In order to ensure the dimensional precision of the casting mold, Fluid Tech built its own mold production workshop and mold repair workshop. All molds and core boxes are designed and produced independently.

At the same time, Fluid tech’s mold production is all completed using high-precision CNC machine tools and automated machining centers. Its technical strength and equipment investment are second to none in the domestic industry.

Our advantage in Molding

1. We have our own mold workshop, we designed, produced and repaired all the molds by ourselves.

2. Our high-precision CNC machine tools and automated machining centers.

3.use the highest specification first-grade water-washed sand to avoid mixing mud and stone, ensuring the smooth surface of the casting mold and ensuring the stability of the casting mold.

4. introduced the internationally advanced Fadilke variable frequency rotor sand mixer to automatically process the molding sand to ensure the humidity and viscosity of the molding sand to improve the stability of the casting mold.

5. We still uses manual molding technology, operated by experienced workers with many years of experience.