Malleable Iron 270 Parallel Thread Socket NPT Thread

Code:270

Size: 1/4”-6”

Material: ANSI/ASTM A197-A,KTH350-10

Dimension: ANSI/ASTM B16.3/14/39

Thread: ANSI/ASTM B1.20.1,NPT

Pressure Rating: 363PSI,CLASS150

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 270 Parallel Thread Socket. Parallel Thread Coupling is a kind of connection pipe fittings. The inner is entire threaded with NPT thread, also named entire thread socket. The another MI coupling is part thread coupling, the inner middle of the coupling is without NPT thread also called part thread socket. The working pressure for these two couplings is 363PSI. For American standard, entire thread socket is much more common but part thread socket also can meet the requirement.

Product Drawing

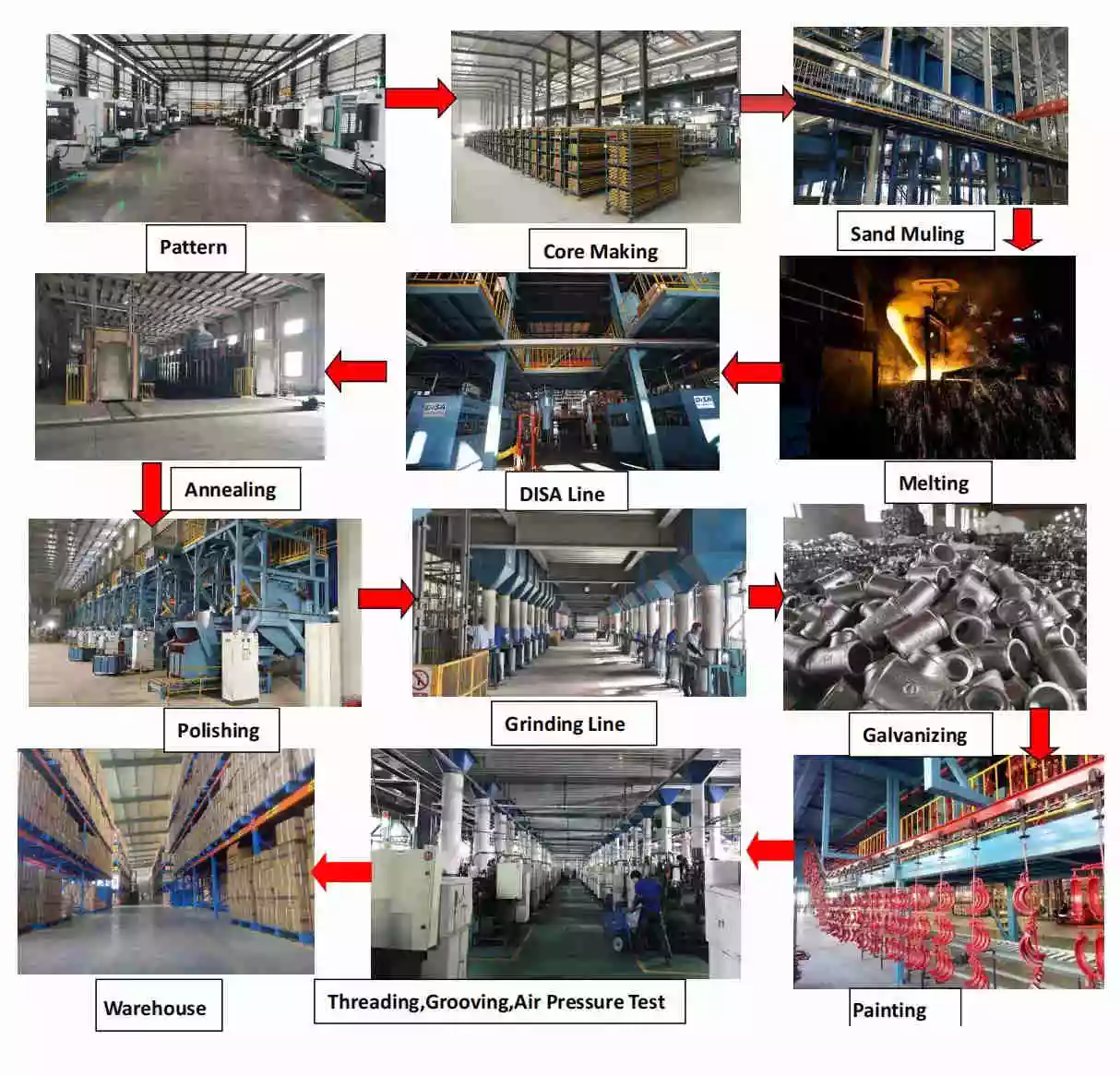

Production process

2. Smelting

Smelting refers to the process of heating raw metal materials to a molten state in preparation for pouring during the casting process.Smelting requires a lot of energy and large equipment. Fuel combustion can cause damage to the environment. Temperature control during the melting process is also crucial. Casting defects caused by undercooling or overheating of the melt

Our advantage in Smelting

1. We all use electric furnaces for smelting to avoid high air pollution caused by fuel combustion in traditional cupola furnaces

2. The material is heated evenly and has a uniform temperature during the melting process, which avoids casting defects caused by overcooling or overheating of the melt during the pouring process.

3. We have introduced an advanced online molten iron carbon-silicon analyzer to analyze the carbon content of iron-carbon alloys during the smelting process, decompose cementite, and ensure the metal composition and performance of castings.