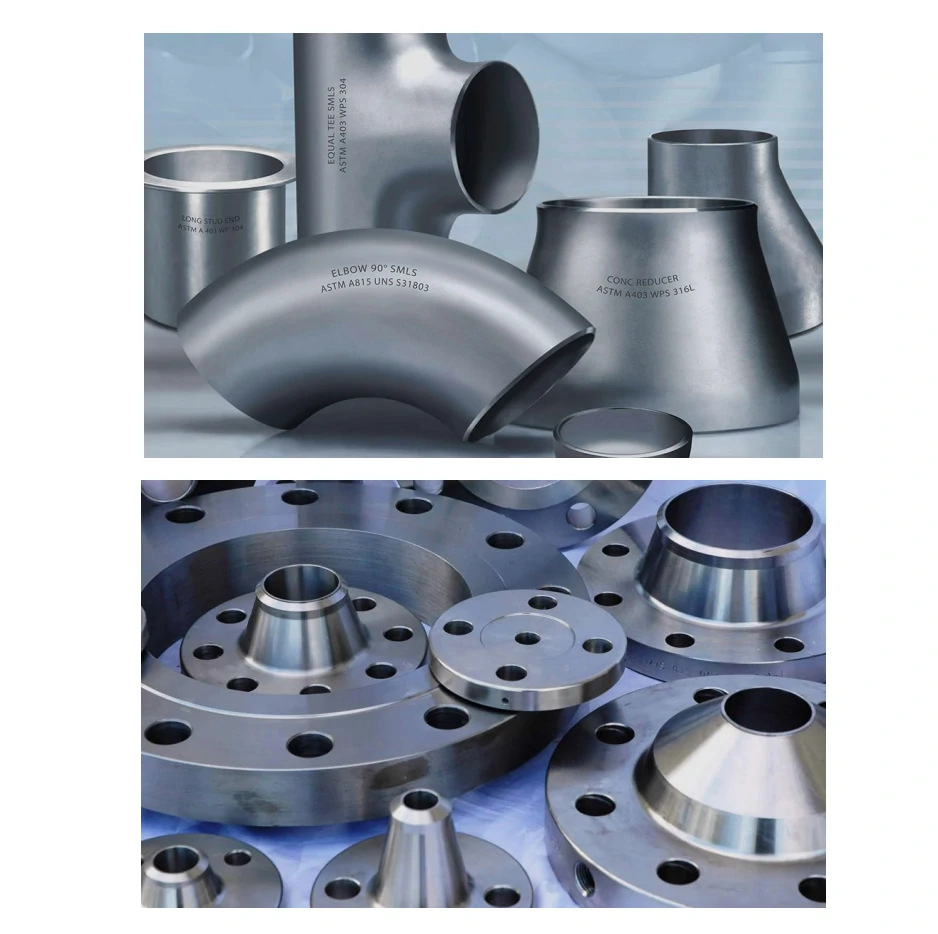

Seam / Seamless Elbow

Certification:ISO, CE

Standard:ANSI B16.9、 ANSI B16.28、 DIN2605/ 2615/ 2616/ 2617、 JIS B2311、 GOST 17375/ 17376/ 17377/ 17378.

Type:45D/90D ELBOW LR/SR

Size:1/2″ – 48″

Wall Thickness:SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, JIS, DIN

Connect Type:Butt Welded

Surface Treatment:Black paint, light oil, hot dip Galvanized.

Material:Carbon steel: ASTM A234 WPB / 20#/ P265GH/ST37.2; Stainless steel: 304/304L, 316/316L

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

The elbow is used when a pipe changes direction. Elbows can turn up, turn down, turn left, right, or any angle in between. The long radius (L/R) elbows denote elbows with the center-to-end dimension of 1.5D radius which equals to 1.5 x NPS in inch unit. The standard long radius elbows can be further classified as 90° and 45° according to the angle of the flow-direction change.

Butt weld fittings have 45D/90D/180D ELBOW LR/SR, EQUAL TEE, REDUCING TEE,CONCENTRIC REDUCER, ECCENTRIC REDUCER, CAP, CROSS, SADDLE.

Product Drawing

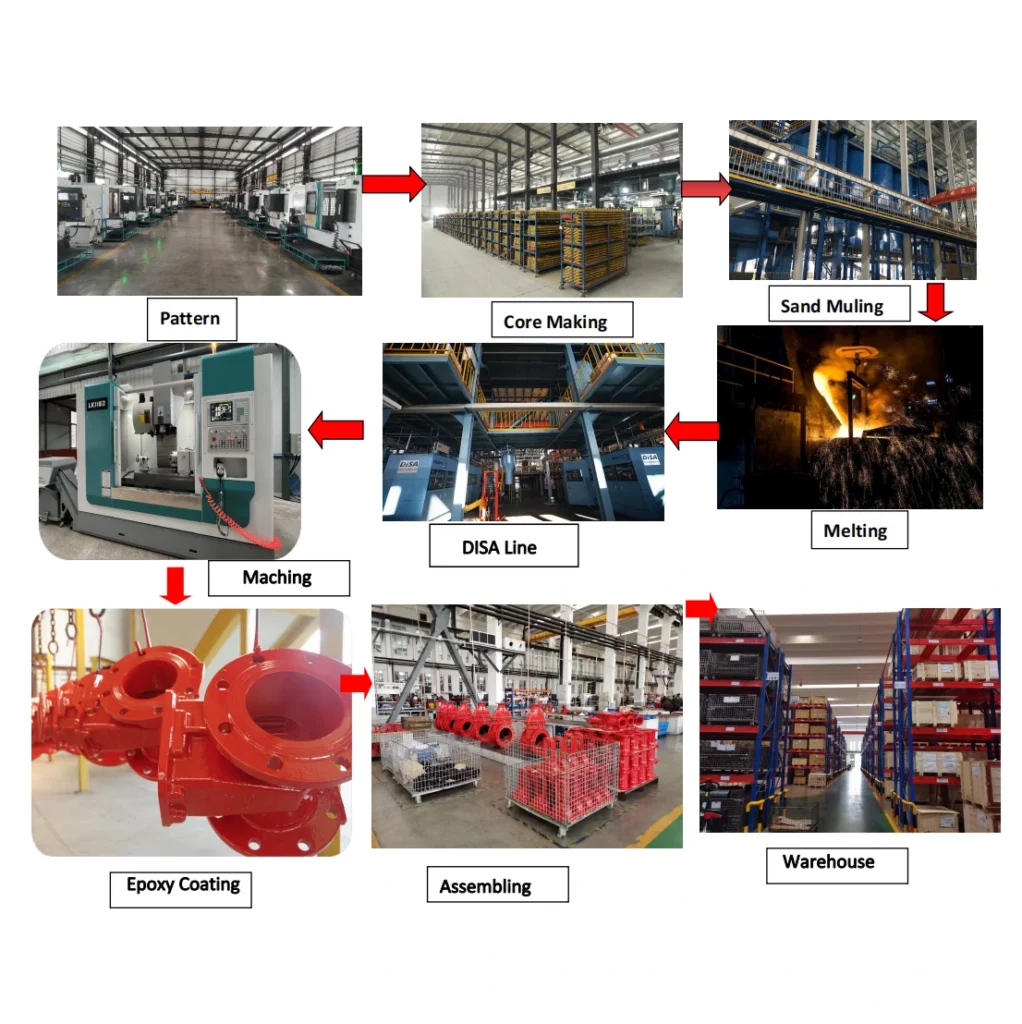

How to make butt welding elbows?

Carbon steel elbow forming is an early application in the mass production elbow forming process, at present, in the common specifications of seamless elbow production has been replaced by hot push method or other forming processes, but in some specifications of elbow due to small production quantity, wall thickness or product special requirements are still used. Carbon steel elbows are formed using a pipe blank equal to the outer diameter of the elbow, which is pressed directly in the mold using a press.

Before stamping, the pipe blank is placed on the lower die, the inner core and end die are loaded into the pipe blank, and the upper die moves downward to start pressing, and the carbon steel elbow is formed by the constraint of the outer mold and the support of the inner mold.

Compared with the hot push process, the appearance quality of stamping forming is not as good as the former; The outer arc of the carbon steel elbow is in a tensile state when forming, and there is no excess metal in other parts to compensate, so the wall thickness at the outer arc is about 10% thinner. However, due to the characteristics of suitable for single-piece production and low cost, the carbon steel elbow process is mostly used for the manufacture of small-batch, thick-walled elbows.

Carbon steel elbows are divided into cold stamping and hot stamping, usually according to the material properties and equipment capacity to choose cold stamping or hot stamping.

The forming process of cold extrusion elbow is to use a special elbow forming machine, put the pipe blank into the outer mold, and after the upper and lower molds are clamped, under the push of the pusher, the pipe blank moves along the gap reserved by the inner mold and the outer mold to complete the forming process.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.