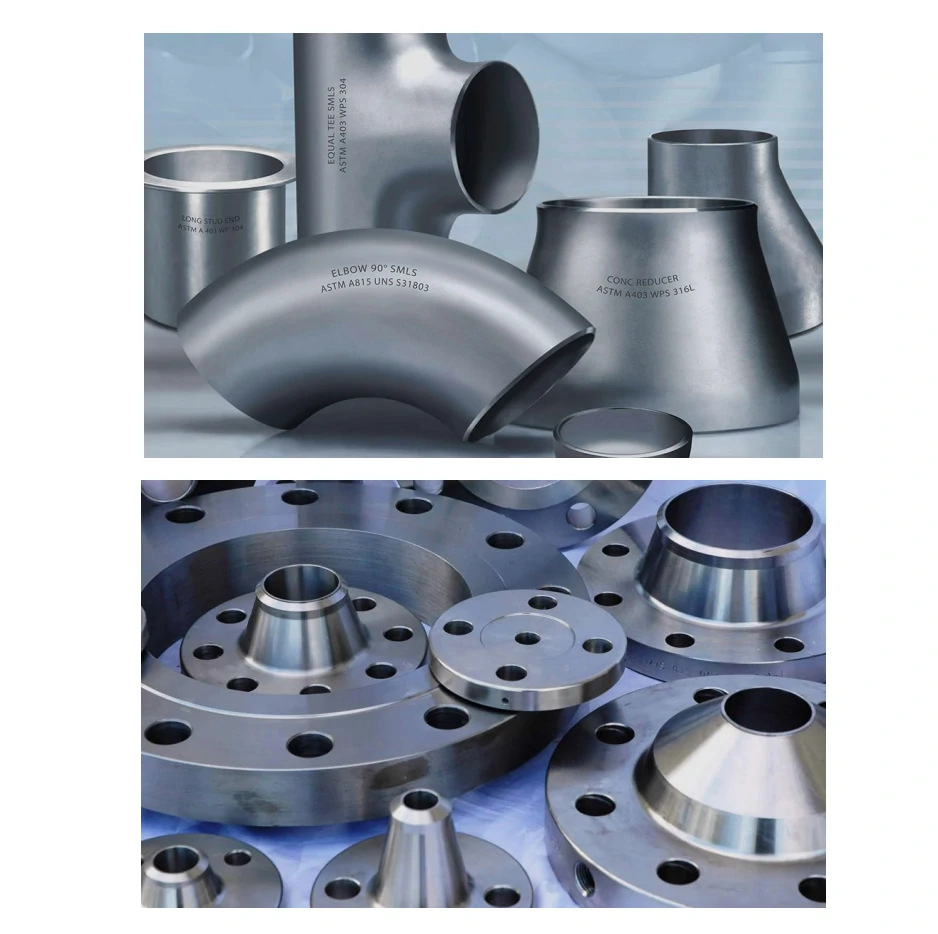

Socket Welding Flanges

Item:Socket Welding Flanges

Certification:ISO, CE

Standard:ANSI B16.5 CLASS 150LBS-2500LBS

Size:1/2″ – 48″

Pressure:CLASS 600LBS FLANGE

Material:Carbon steel ASTM A105/A105N; A694 F42-F70; A-350 LF1/LF2; Stainless steel ASTM A182 F304/304L; F316/316L; F321; F51; Alloy steel ASTM A182 F11/F12/F22

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Socket welding flange is similar to a slip-on flange except it has a bore and a counterbore dimension. The counterbore is slightly larger than the O.D. of the matching pipe, allowing the pipe to be inserted into the flange similar to a slip-on flange. The diameter of the smaller bore is the same as the I.D. of the matching pipe A restriction is built into the bottom of the bore which sets as a shoulder for the pipe to rest on. This eliminates any restriction in flow when using a socket welding flange.

Flange is also called flange or flange. The flange is the part that connects the tube to the tube, connected to the end of the tube. There are bolt holes on the flange, and the bolt makes the two flanges closely connected. The flange is usually sealed with a gasket (flange gasket).

According to the material division, common are cast iron/carbon steel flange, stainless steel flange, PVC/PPR flange, etc.; According to the connection method, it can be roughly divided into threaded connection (wire connection) flange and welding flange, of which the welding flange can be divided into flat welding flange, butt welding flange, flange blind plate and other varieties. According to the tolerance pressure level, the common ones are 0.6Mpa, 1.0Mpa, 1.6Mpa, 2.5Mpa, 4.0Mpa, 6.4 Mpa, 10.0Mpa and so on.

Product Drawing

How to learn more about flange?

Iron plate flange performance:

1. Use media such as water, alcohol, ammonia, barium carbonate, benzene (WCB material temperature use -29 °C-425 °C).

2. Use media such as granules, oil, pulp, carbon dioxide gas (stainless steel material can use temperature -60 °C-232 °C).

3. It is strictly forbidden to use fluoride-containing ionic liquids (such as HF, etc.) and cannot use strong alkali and phosphoric acid (temperature less than 150 °C, concentration > 30%).

4. The general working temperature of stainless steel ≤ 150 °C, the pressure range is 0.6-2.5MPA, which should be explained when ordering more than this regulation.

Iron plate flange according to different grades of pressure, flange pads also have different materials, from low-pressure asbestos pads, high-pressure asbestos pads to metal pads.

1. Carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon asphalt, PPC, etc. by material.

2. According to the production method, it can be divided into forged flange, casting flange, welding flange, rolled flange (oversized model).

3. According to manufacturing standards, it can be divided into national standards (Ministry of Chemical Industry standards, petroleum standards, power standards), American standards, German standards, Japanese standards, Russian standards, etc.

German standard 2576 (PL type) flange is mainly a part that connects the pipe to the tube. According to the structural type, there are integral flanges, looper flanges and threaded flanges. Common integral flanges include flat welding flanges and butt welding flanges. Flanged fittings refer to pipe fittings with flanges (flanges or splices). It can be cast or threaded or welded.

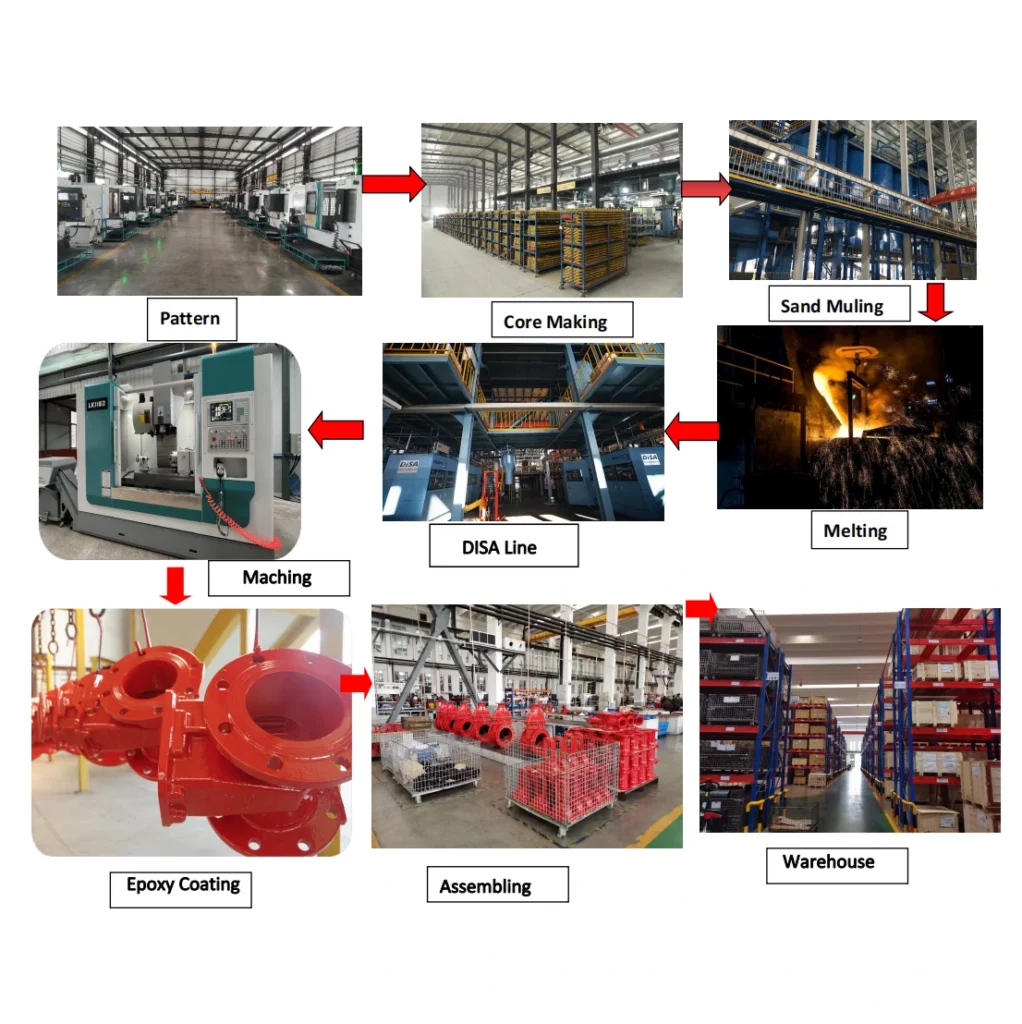

The maintenance process of large-scale flange production equipment is as follows:

The production equipment of large flanges is mainly maintenance-oriented. Maintenance work is an aid. Partial disassembly and inspection of the equipment is carried out as planned. Clean the specified parts, unblock the roads and pipelines. Exchange or clean the oil washing line and oil filter, adjust the matching gap between the equipment parts of the large flange, tighten the loose bolts, and replace the bolts that cannot be used in time. Ordinary maintenance can be done once a month. Large-scale maintenance is mainly based on maintenance workers, specific operators participate, and are included in the monthly maintenance plan of the equipment. Such a major maintenance is to repair and inspect some key parts of the large flange, replace some wearing parts, and trim the electrical part. Local critical positions restore accuracy to meet the lower requirements for machined parts. You just want to keep the equipment running, not the maintenance. No, only the combination of use and maintenance and repair can make large flange equipment serve the factory.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.