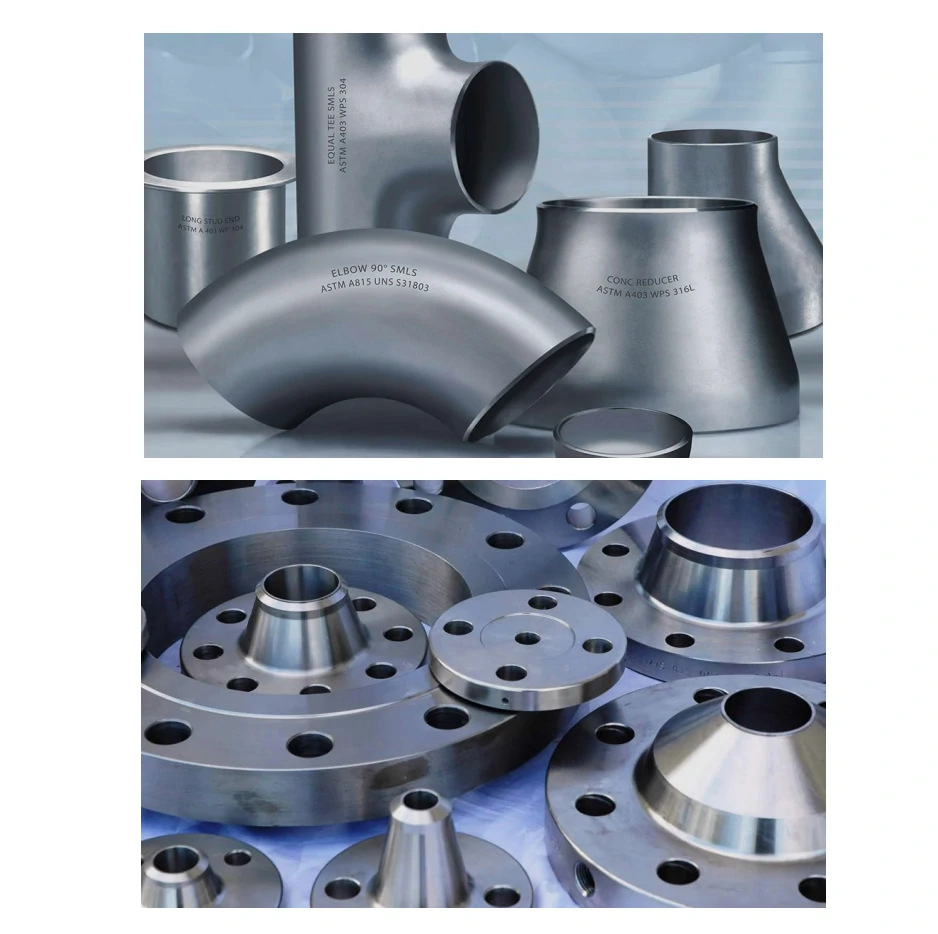

Blind Flanges

Item: Blind Flanges

Certification:ISO, CE

Standard:ANSI B16.5 CLASS 150LBS-2500LBS

Size:1/2″ – 48″

Pressure:CLASS 600LBS FLANGE

Material:Carbon steel ASTM A105/A105N; A694 F42-F70; A-350 LF1/LF2; Stainless steel ASTM A182 F304/304L; F316/316L; F321; F51; Alloy steel ASTM A182 F11/F12/F22

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Blind flanges is a flange without a bore. It is used to close off the ends of a piping system and/or pressure vessel opening. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

Uses of flanges:

As far as flange / flange sheet is concerned, although most people are very unfamiliar with this concept, but in fact, every urban person can not do without it, because flange is widely used in the interconnection of various high, medium and low pressure pipelines, such as urban water supply pipeline network, sewer drainage pipe network, winter boiler heating circulation pipeline, oil and gas and other energy pipelines, etc. are inseparable from it, and its role in pipelines is equivalent to the connection between the rails and the rails on the railway that we are familiar with.

Specifications of the flange:

From small to large, the common specifications are: DN 10, DN15, DN20, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN 175, DN200, DN225, DN250, DN300, DN350, DN400, DN450, DN500, DN600, DN700, DN800, DN900, DN1000, DN1200, DN1400, DN1600, DN1800, DN2000, DN2200, DN2400, DN2600, DN2800, DN3000, etc.

Product Drawing

How to learn more about Blind flange?

Special-shaped flanges are used as sealing and fastening connectors, also known as special-shaped flanges. It has a wide range of applications in large containers in aerospace, petroleum, chemical and other fields. Although the problem of processing capacity is not considered, for special-shaped flanges, because their size is too large, only due to transportation reasons, the overall processing of special-shaped flanges is impossible, split lobe processing.

peculiarity

Typically, the special-shaped flange is always machined into several arc segments. First, the blank is forged into a billet, then cold-bent into arc segments, annealed to stress relief heat treatment, spliced into a whole circle on the vertical car to process to the designed shape and size, transported to the construction site, and then weld several arc segments into a complete special-shaped flange and weld it with the pressure vessel group.

Since the nominal diameter of the container barrel of the special-shaped flange and the specific size represented by the nominal diameter of the pipe are different, the container flange and the pipe flange of the same nominal diameter are not the same size, and the two cannot be used interchangeably.

standard

Production and implementation standards of special-shaped flanges: national standard, American standard, Japanese standard, German standard, Italian standard, chemical department standard, machinery department standard, pressure vessel standard.

The pressure level, material, standard, etc. of special-shaped flange have different characteristics and characteristics, and can be produced and processed in accordance with the corresponding standards in accordance with the principle and method and method used in use, ensuring that it has good use value and role in use. Special-shaped flange pressure grade: 0.6Mpa~32Mpa (150Lb~2500Lb) special-shaped flange material: 201.202.301.302.303.304L.309S.310S, 316.316L.317.317L.321.410.420, etc. Special-shaped flanges have different production standards in use and production, and the production and use in accordance with the corresponding standards can ensure the use value and role of special-shaped flanges in practice.

Application and Case

Blind Flanges are used in water system, HVAC system, plumbing, gas system etc.Steel Pipe Fitting are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.