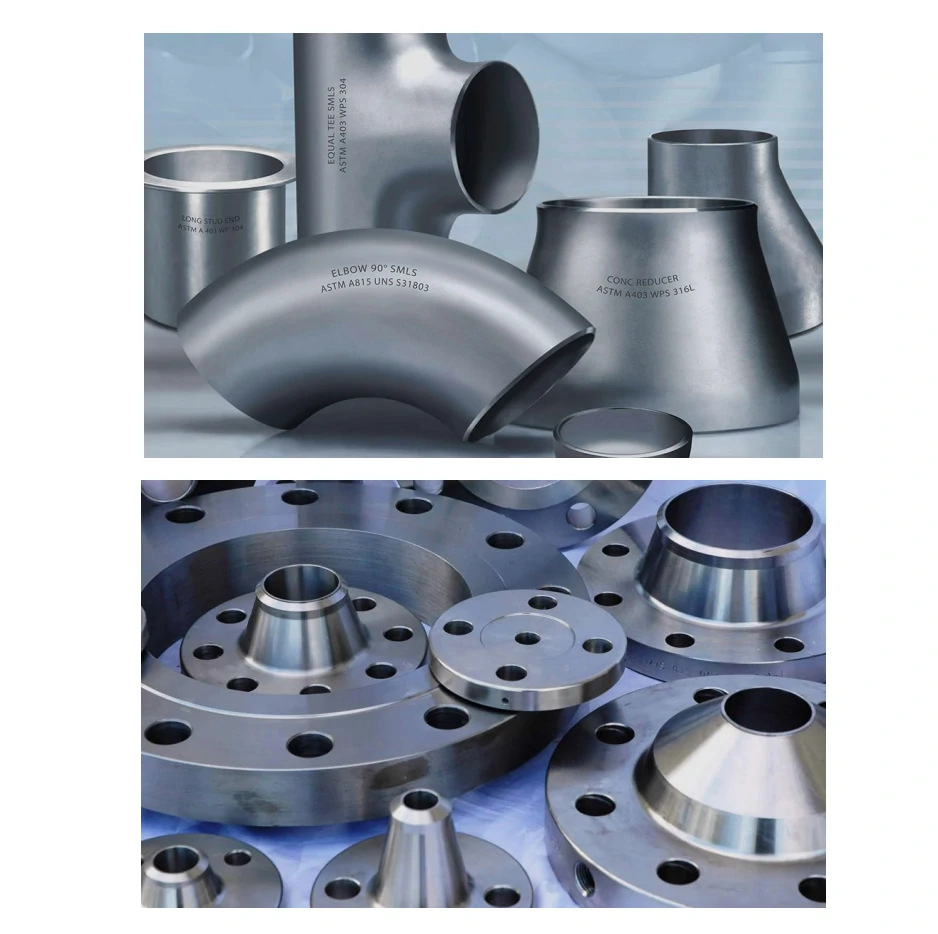

Cap Butt-Welding pipe Fitting

Certification:ISO, CE

Standard:ANSI B16.9、 ANSI B16.28、 DIN2605/ 2615/ 2616/ 2617、 JIS B2311、 GOST 17375/ 17376/ 17377/ 17378.

Type:CAP

Size:1/2″ – 48″

Wall Thickness:SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, JIS, DIN

Connect Type:Butt Welded

Surface Treatment:Black paint, light oil, hot dip Galvanized.

Material:Carbon steel: ASTM A234 WPB / 20#/ P265GH/ST37.2; Stainless steel: 304/304L, 316/316L

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

The cap is used to seal an open end of the pipe. In piping engineering, the cap made in accordance with ASME B16.9 will be welded to the end and need not be included in the length dimension of the run of pipe.

Product Drawing

How to check welded cap?

Pipe cap, casing) cap, also known as head, plug, cap, pipe cover, stuffed head, welded to the pipe end or mounted on the pipe end external thread to cover the pipe fittings. It is used to close pipelines, and the function is the same as pipe plugging.

When splicing, the weld direction requirement is only allowed to be radial and circumferential. This requirement may be removed in the future for large caps. The distance of the splicing should be required, which is greater than 3δ and not less than 100mm (the welding heat-affected zone is a high-stress zone, and the chemical composition in this zone will be burned. So avoid areas of high stress, which are related to thickness. According to practical experience, the stress attenuation length is greater than 3δ and not less than 100mm). However, it is difficult for refrigeration equipment to meet this requirement and has its own particularities.

The splicing of the formed head, the splicing weld should be 100% ray or ultrasonic inspection, and the qualified level goes with the equipment shell. The inspection level and proportion of the formed weld seam are the same as the equipment housing, which is high waste.

Example: If the device housing is 20% tested, III is qualified. That stuffy splicing weld and weld are also III qualified, and the welding joint coefficient is 0.85;

If the device housing is 100% inspected, II is qualified. That stuffy splicing weld and weld are also II qualified, and the welding joint coefficient is 1

Therefore, although the stuffy splicing is 100% detected, the qualification level is not the same, and it goes with the equipment shell.

But pay attention to the process manufacturing process:

The correct approach is: blanking (scribbing) - small plates put together into large plates - forming - non-destructive testing.

If it is not tested before molding, it is not right, and the quality of the product after molding cannot be guaranteed. In other words, non-destructive testing refers to the final non-destructive testing.

Application and Case

Cap Butt-Welding pipe Fitting are used in water system, HVAC system, plumbing etc.Butt-Welding Pipe Fitting are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.