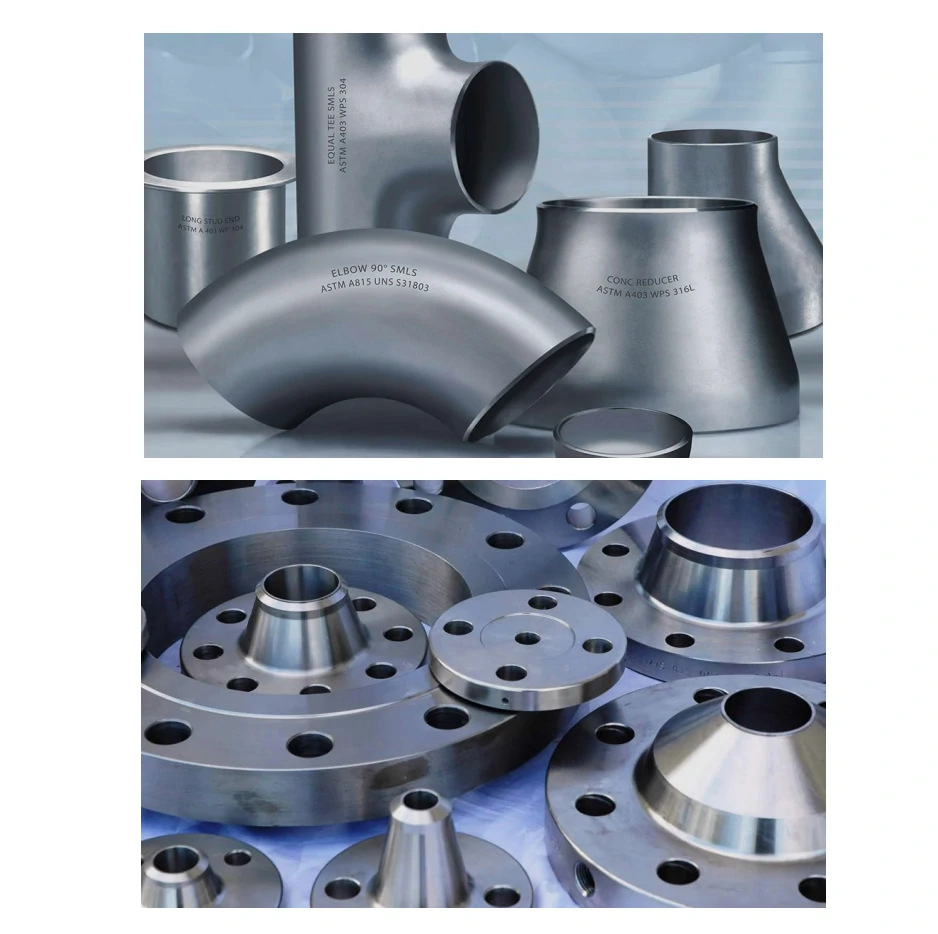

Seam / Seamless Tee

Certification:ISO, CE

Standard:ANSI B16.9、 ANSI B16.28、 DIN2605/ 2615/ 2616/ 2617、 JIS B2311、 GOST 17375/ 17376/ 17377/ 17378.

Type:EQUAL TEE, REDUCING TEE,CROSS

Size:1/2″ – 48″

Wall Thickness:SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS, JIS, DIN

Connect Type:Butt Welded

Surface Treatment:Black paint, light oil, hot dip Galvanized.

Material:Carbon steel: ASTM A234 WPB / 20#/ P265GH/ST37.2; Stainless steel: 304/304L, 316/316L

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

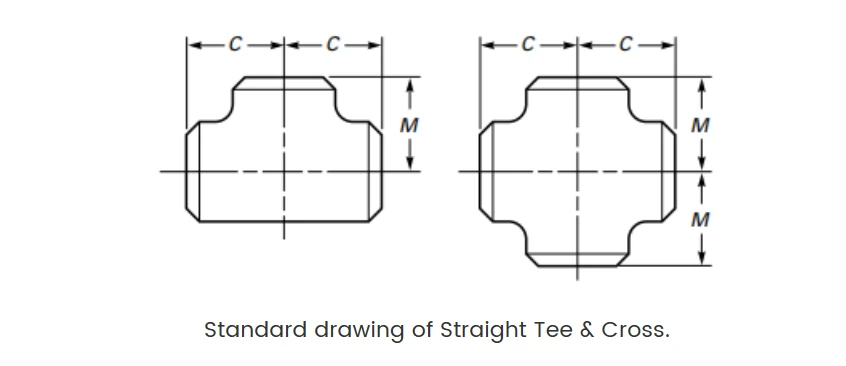

The straight tee is a three-way fitting used to make perpendicular connections to a pipe. Its name comes from its resemblance to the letter T. The straight cross is a four-way fitting used to make double perpendicular connections to the pipe. It resembles a crossroad. Lines that connect to the main run of pipe are knownn as “branches”. The main run of pipe is often called the “header”. The word “straight” denotes that all three(for tee) or four(for cross) outlets are the same pipe size.

Product Drawing

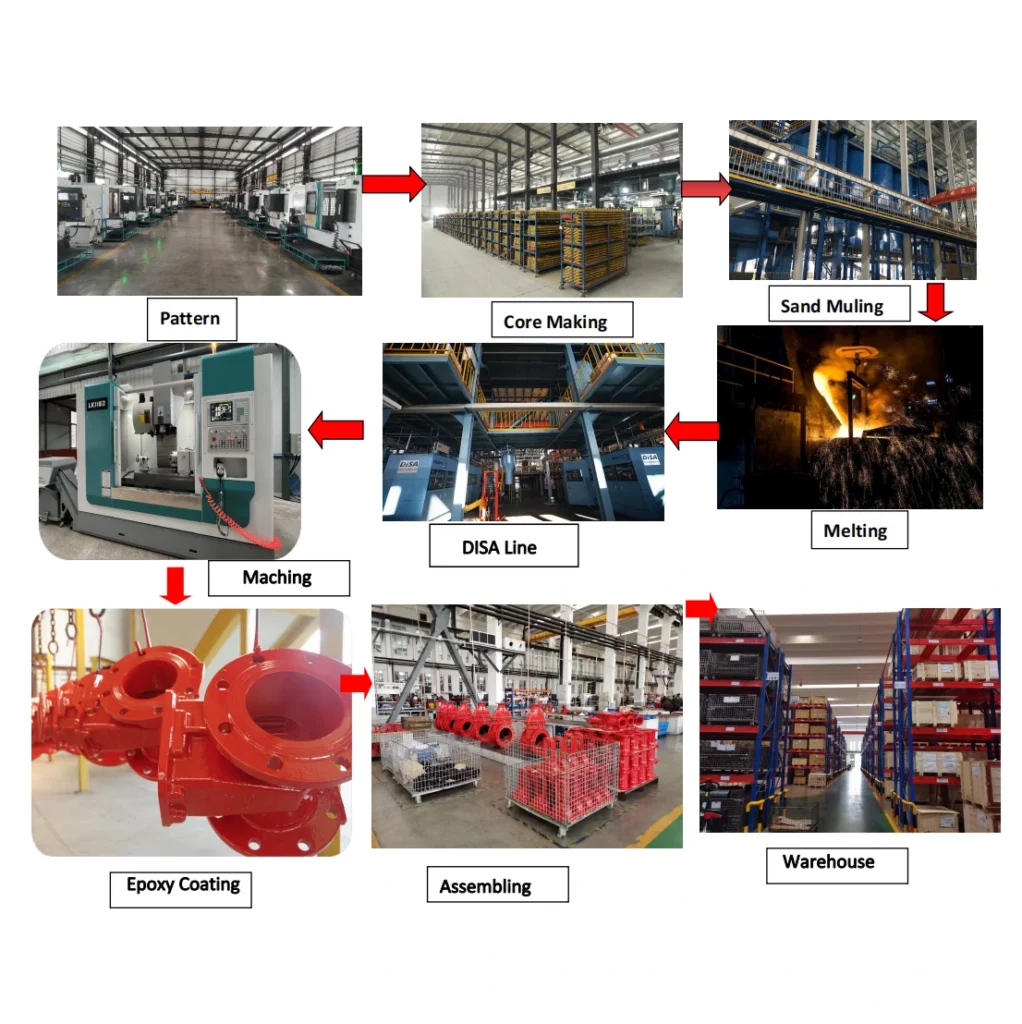

How to make butt welding Tee and Cross?

Tee is also known as pipe fittings tee or tee fittings, tee joints, etc. It is mainly used to change the direction of the fluid, and is used in the main pipeline to branch the pipe. Can be classified by pipe diameter. It is generally made of carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon asphalt, PVC and other materials.

1. Hydraulic expansion

The hydraulic expansion of the tee is a forming process in which the branch pipe is compensated by the axial direction of the metal material. The process is to use a special hydraulic press, and the three-way diameter equal to the pipe blank injected liquid, through the hydraulic press two horizontal side cylinders synchronous alignment movement to extrude the pipe blank, the volume of the pipe blank after being squeezed becomes smaller, the liquid in the pipe blank with the volume of the pipe blank becomes smaller and the pressure rises, when the pressure required for the expansion of the tee branch pipe is reached, the metal material flows along the mold cavity under the dual action of the side cylinder and the liquid pressure in the pipe blank and expands the branch pipe.

The hydraulic expansion process of the tee can be formed at one time, and the production efficiency is high; The main and shoulder wall thickness of the tee has increased.

Due to the large tonnage of equipment required for the hydraulic expansion process of seamless tee, it is currently mainly used in the manufacture of standard wall thickness tees smaller than DN400 in China. Its applicable forming materials are low carbon steel, low alloy steel, stainless steel with relatively low cold work hardening tendency, including some non-ferrous metal materials, such as copper, aluminum, titanium, etc.

2. Hot press forming

Tee hot pressing is to flatten the pipe blank larger than the diameter of the tee to the size of the tee diameter, and make a hole in the part of the stretched branch pipe; The pipe blank is heated, put into the forming die, and the die of the stretched branch pipe is loaded into the pipe blank; Under the action of pressure, the pipe blank is compressed radially, and in the process of radial compression, the metal flows in the direction of the branch pipe and forms a branch pipe under the stretching of the die. The whole process is formed by the radial compression of the pipe blank and the stretching process of the branch pipe part. Unlike hydraulic expansion tees, the metal of hot-pressed tee branch pipes is compensated by the radial movement of the pipe blank, so it is also called a radial compensation process.

Due to the use of pressed tees after heating, the tonnage of equipment required for material forming is reduced. The hot-pressed tee has wide adaptability to the material and is suitable for materials of low carbon steel, alloy steel and stainless steel; In particular, tees with large diameters and thick walls are usually formed in this way.

Application and Case

Seam / Seamless Tee are used in water system, plumbing, gas system, irrigation system, etc.Butt-Welding Pipe Fitting are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.