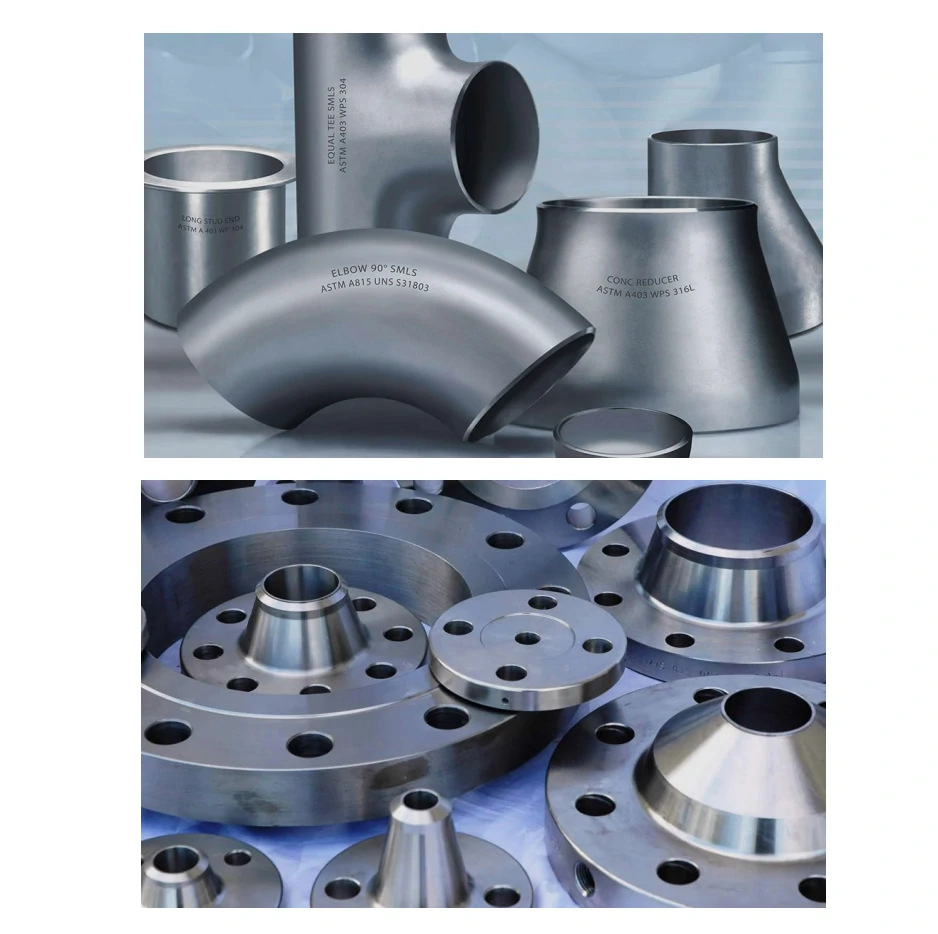

Welding Neck Flanges

Item: Welding Neck Flanges

Certification:ISO, CE

Standard:ANSI B16.5 CLASS 150LBS-2500LBS

Size:1/2″ – 48″

Pressure:CLASS 600LBS FLANGE

Material:Carbon steel ASTM A105/A105N; A694 F42-F70; A-350 LF1/LF2; Stainless steel ASTM A182 F304/304L; F316/316L; F321; F51; Alloy steel ASTM A182 F11/F12/F22

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Weld neck flanges are often referred to as “high raised” flanges. It is designed to transfer stress to the pipe, thereby reducing the high stress concentration at the bottom of the flange. The weld neck flange is currently the best butt weld flange available due to its inherent structural value. It is expensive due to the design.

Product Drawing

High-pressure flange is mainly used in the installation of pipelines, high-pressure flange connection is an important connection method of pipeline construction, mainly connecting the connection between pipes and pipes, playing an important role and value. High-pressure flange connection is to fix two pipes, pipe fittings or equipment on a flange plate first, and between the two flanges, plus flange pads, bolts are fastened together to complete the connection. Some pipe fittings and equipment already have their own flanges, which are also flange connections.

High pressure flange product performance:

1. Properties: The Al2O3 content in the ceramic layer lined with ceramic composite steel pipe is greater than 95%, and the microhardness HV1000-1500 has the property, which is more than ten times higher than that of quenched medium carbon steel, which is better than tungsten diamond cemented carbide.

2. Ceramics are neutral materials, stable chemical properties, excellent corrosion resistance and acid resistance, can resist various inorganic acids, organic acids, organic solvents, etc., and its degree of corrosion resistance is more than ten times that of stainless steel.

Material

Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70

Stainless steel (Stainess Steel): ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo,

Material: [1] (nickel steel), WC5 (1.25% chromium 0.5% molybdenum steel), WC9 (2.25% chromium), C5 (5% chromium % molybdenum), C12 (9% chromium 1% molybdenum), CA6NM (4 (12% chromium steel), CA15 (4) (12% chromium), CF8M (316 stainless steel), CF8C (347 stainless steel), CF8 (304 stainless steel), CF3 (304L stainless steel), CF3M (316L stainless steel), CN7M (alloy steel) , M35-1 (Monel), N7M (Haast nickel alloy B), CW6M (Hasta nickel alloy C), CY40 (Inko nickel alloy).

Application and Case

Welding Neck Flanges are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.Carbon Steel Flange are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.