Product Description

Products Details

What is the thread welded outlet ,Threadolet?

A threadolet is used for low-pressure 90-degree pipe branches. It has a female threaded connection, and the branched pipe is screwed on the fitting. This makes the 90-degree branch a full-size or reduced straight pipe. A full-size threadolet offers the same diameter branch as the run pipe.Weldolets are the most popular type of branch fittings, belong to the buttweld fittings family, and are available in a wide range of dimensions.

A Weldolet has beveled ends at both ends and is, therefore, welded onto the run pipe on one side and onto the branch pipe on the other side. Weldolets are used to create a 90-degrees (reinforced) pipe branch. The shape of the Weldolet ensures little stress concentration on the branched pipe, providing an integral reinforcement.

On the branch pipe side, Weldolets may have the same schedule of the run pipe or a higher schedule.

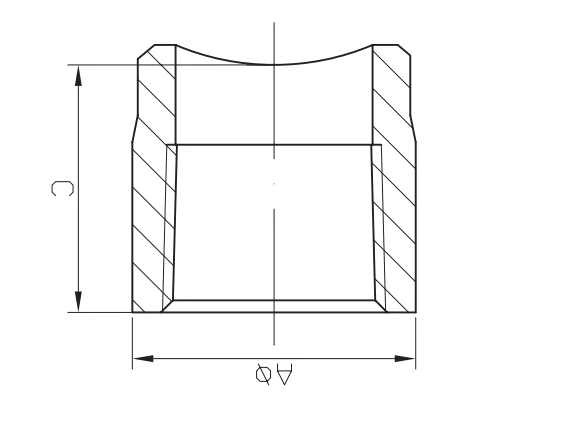

Product Drawing

What’s the threadolet,Weldolet, Threadolet, Sockolet?

What are branch connections (or pipe branch outlet fittings aka “Olets”)? Olet fittings are a family of forged products used to make 45 or 90 degrees integrally reinforced branch connections (deviations) from a run pipe (also called, header pipe) to a branch pipe (outlet pipe). The common types of branch fittings are Weldolet, Thredolet, Sockolet, Latrolet, Elbolet, Nipolet, Sweepolet. MSS-SP 97 is the key specification covering reinforced branch connections, introduced by Bonney Forge in the piping market more than 70 years ago.Pipe branch fittings are used to create integrally reinforced connections from a run pipe (header pipe) to an outlet pipe, at 45 or 90 degrees, alternatively to connections made with buttweld tees, reinforcing pads and saddles. This type of forged fittings are otherwise called “branch connections”, or “branch fittings”, or “pipe branch outlet fittings” or, simply, “Olets”.

Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques.

How are they installed? Quite easily: on one side, the fittings (example a Weldolet) is fixed onto the run pipe with a full penetration groove weld and, on the other side, welded (or screwed) on the branch pipe. Of course, the header pipe shall be properly cut in the proximity of the area where the pipe needs to be branched.

A Sockolet is similar to a Weldolet, with the difference that the branch pipe is connected to the run pipe, via the fitting, with a socket weld connection as per ASME B16.11. Likewise Weldolets, Sockolets are used to make a 90-degree pipe branch. Sockolets may be “size on size” or “reducing”.

Fillet welds are used to connect the branch pipe to the branch side of the Sockolet. On the pipe run side, a Sockolet requires a welded connection.

Thredolets are used for low-pressure 90-degree pipe branches. The branch pipe is screwed on the Thredolet, which is welded on the run pipe. The threading is generally of the NPT type and conforms to the ASME B1.20.1 specification.

Thredolets belong to the “threaded fittings” family and are available in classes 3000# and 6000#. Threadolets are used for smaller pipe sizes and low-pressure applications.

Latrolets branch a pipe at 45 degrees. They are available with butt weld connections to meet demanding reinforcement requirements or with socket weld/threaded connections in classes 3000# or 6000#.

Elbolets are used with 90 or 180 degrees long radius and short radius (more rarely) elbows for thermowell and instrumentation connections or as a drain connection when there is too little space for using a Weldolet.

Elbolets are available with butt weld connections or with socket weld/threaded connections in classes 3000# or 6000#.

Nipolets are used for valve take off, drains and vents and are manufactured in lengths between 3 1/2 to 6 1/2 inches and for XS and XXS schedules. A Nipolet is welded onto the run pipe and is manufactured with socket weld or threaded outlets on the branch pipe side.

Sweepolets are contoured, integrally reinforced, buttweld branch fittings used for low stress and long fatigue service. The welded connection on the run pipe side can be easily inspected with radiographic examination (RX or RT), ultrasounds (UT) and other non-destructive tests.

Application and Case

Products are used in fire protection system, water system, HVAC system, plumbing, gas system, irrigation system, etc.These products are used in many projects , such as Beijing Airport, Shanghai World Trade Center, Canton Tower and other famous landmark projects.