Malleable Iron 301 Round Cap NPT Thread

Code:301

Size: 1/4”-6”

Material: ANSI/ASTM A197-A,KTH350-10

Dimension: ANSI/ASTM B16.3/14/39

Thread: ANSI/ASTM B1.20.1,NPT

Pressure Rating: 363PSI,CLASS150

Surface Treatment:Hot-dip Galvanized,Electro Galvanized,Black

Zinc Coating: ASTM A 153

Certificate: UL Listed / FM Approved / NSF 61

Application: Fire Protection,Waterworks,HVAC,Plumbing,GAS,Irrigation,or other piping systems

We’re here to help:

Easy ways to get the answers you need.

Product Description

Products Details

Malleable Iron 301 round Cap. 301 round cap can be threaded with NPT, mainly for American standard pipes. The maximum working pressure for class 150 pipe fittings is 363PSI, 2.5Mpa. Round cap can be black surface for fire-fighting system or Hot-dip galvanized/Electro Galvanized for water,plumping system.

Product Drawing

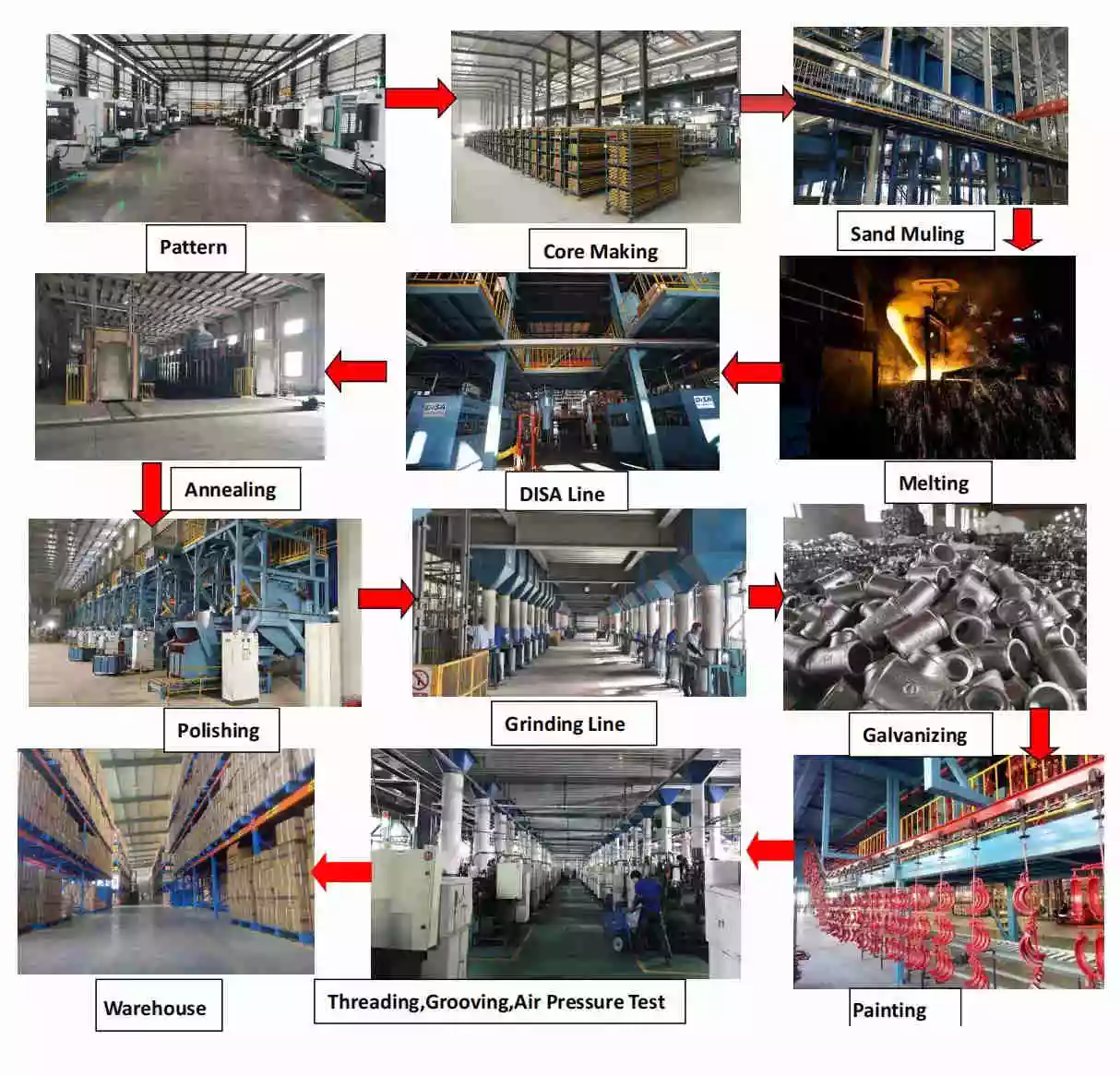

The process:

4-Annealing

Annealing is a metal heat treatment process, which refers to slowly heating the metal to a certain temperature, maintaining it for a sufficient time, and then cooling it at an appropriate speed. This process can change the hardness, strength, toughness and other physical properties of the metal, making it more suitable for processing and manufacturing various products. The annealing process can adopt different parameters such as heating temperature, heating speed, holding time and cooling speed to achieve different processing effects. For example, high-temperature annealing can eliminate residual stress inside the metal and make the metal more stable; low-temperature annealing can improve the plasticity and toughness of the metal, making it more suitable for operations such as forming and welding.

The Purpose of annealing for pipe fittings

1. Improve or eliminate various structural defects and residual stress caused by steel casting, forging, rolling and welding processes to prevent workpiece deformation and cracking.

2. Reduce the hardness and soften the pipe fittings for cutting.

3. Refine the grains, improve the structure and eliminate structural defects to improve the mechanical properties of the workpiece.

The annealing process can adopt different parameters such as heating temperature, heating speed, holding time and cooling speed to achieve different processing effects.